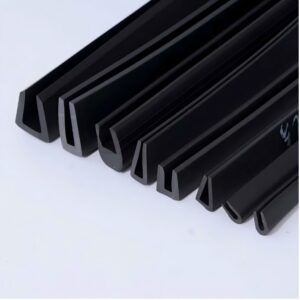

PVC / TPU / TPE Sealing Strip Profile Extrusion Line

Key Selling Points

- Efficient Output: Stable performance with high output and low energy consumption for cost-effective production

- Smart Automation: Inverter, SIEMENS PLC, and screen technology enable easy operation with precise monitoring

- Adaptable Design: Different L/D ratios and barrel structures handle various raw materials and specifications

- Multi-Material Capability: Patented casting technology effectively processes PVC, TPU, and TPE with consistent quality

Main Technical Parameter

| Extruder Model | Output | Installed Power | Dimensions (LxWxH) | Product Thickness | Price |

| JWS45/25 | 15 – 25KG/H | 55KW | 14m*1.4m*2.3m | 0.4 – 1.0mm | USD 21K, FOB Shanghai |

| JWS65/25 | 40 – 60KG/H | 55KW | 14m*1.4m*2.3m | 0.4 – 2.0mm | USD 25K, FOB Shanghai |

Application Scenarios

Product Description

Our advanced co-extrusion line produces high-quality composite profiles with superior performance and flexibility. This system delivers efficient production with customizable options to meet diverse material and specification requirements.

Key Features

- High-Performance Production: The extrusion line delivers stable performance, high output, and low energy consumption. It ensures reliable and cost-effective manufacturing for continuous production demands.

- Advanced Control System: The line features famous inverter, SIEMENS PLC, and screen technology. This enables easy operation and maintenance with precise control and monitoring capabilities.

- Customizable Configuration: According to different raw materials and product specifications, the screw adopts different L/D ratios and compression ratios. The barrel features different structures for specialized co-extrusion applications to meet diversified production needs.

- Superior Material Handling: The specially designed patented cast composite molding technology handles different materials such as PVC, TPU, and TPE effectively. It ensures consistent product quality and performance across various material types.