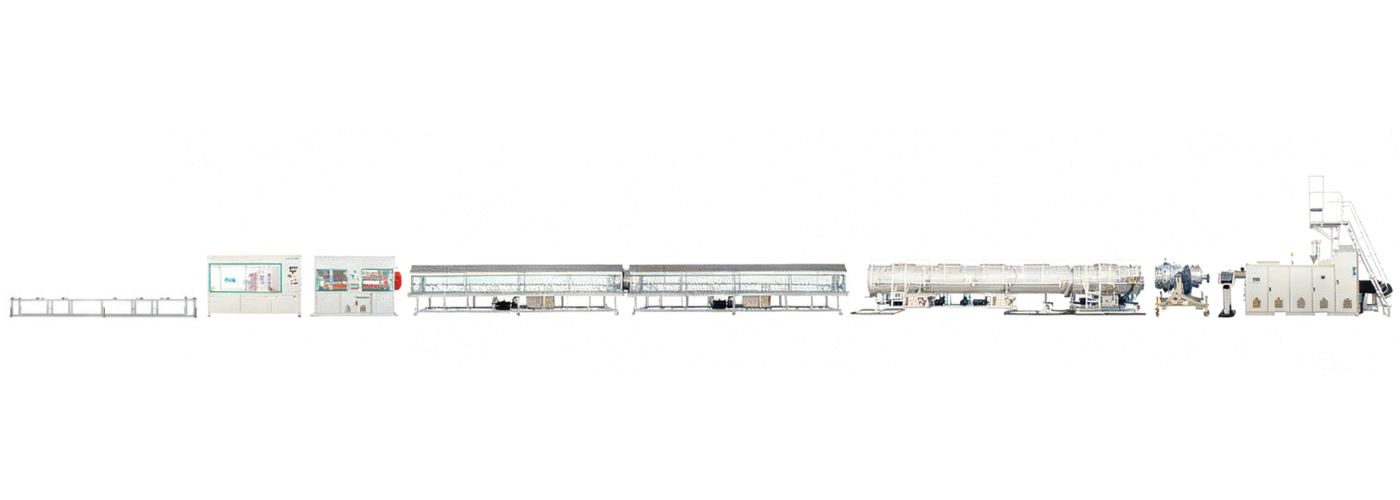

MPP Polypropylene Power Cable Conduit Extrusion Production Line

Key Selling Points

- High-Performance Extrusion: Servo motor, high-torque reducer, energy-saving heating, excellent plasticizing

- Advanced Non-Stick Mold: Superior heat treatment, uniform thick-wall extrusion, fast changeover

- Precision Cooling & Haul-Off: Powerful vacuum spray cooling, synchronized servo-driven multi-track traction

- Industry 4.0 Smart Monitoring: Real-time production & energy data, remote access via PC/App

Main Technical Parameter

| Raw Material | Output | Type | Installed Power | Dimensions (LxWxH) | Pipe I.D. | Price / $ |

| MPP | 380KG/H | JWG-160 | 205KW | 45mx3mx4m | 50mm – 160mm | USD 55K – 208K, FOB Shanghai |

| MPP | 640KG/H | JWG-250 | 296KW | 49mx3.6mx4.5m | 75mm – 250mm | USD 55K – 208K, FOB Shanghai |

| MPP | 680KG/H | JWG-315 | 302KW | 50mx3.6mx4.5m | 110mm – 315mm | USD 55K – 208K, FOB Shanghai |

| MPP | 730KG/H | JWG-400 | 580KW | 60mx5mx5m | 160mm – 400mm | USD 55K – 208K, FOB Shanghai |

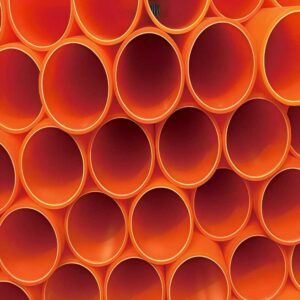

Application Scenarios

Product Description

The JWELL MPP Pipe Extrusion Line is a high-performance manufacturing system engineered for efficient production of modified polypropylene pipes with advanced servo-driven technology and intelligent control systems.

- High-Performance Extrusion System: The extruder integrates a servo motor with a high-torque reducer and an energy-saving heating system. Its screw is engineered for excellent material plasticizing performance, ensuring a stable, high-quality melt.

- Advanced Die Head & Cooling Technology: The mold surface features an advanced heat treatment for non-stick, high-capacity extrusion and fast material changes. It’s designed to produce thick-walled pipes with minimal melt sag and uniform thickness. This is paired with a powerful multi-stage vacuum spray system for rapid and efficient cooling.

- Precision Synchronized Haul-Off: A long-contact, multi-track haul-off unit, with each track independently controlled by a servo motor, guarantees precise speed synchronization during both high and low-speed operation for consistent pipe quality.

- Smart Remote Monitoring: The line is equipped with an intelligent control system that displays real-time production data, including output capacity and energy consumption costs per ton. All data is accessible for remote viewing on a PC or through a mobile app.