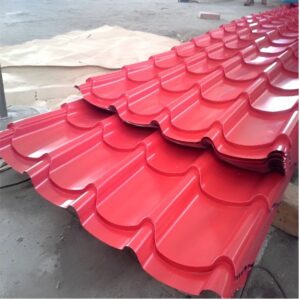

PVC Single / Multi Layer Resistance Heat Corrugated Roofing Extrusion Line

Key Selling Points

- Advanced Temperature Management: SJZ92 extruder ensures precise plasticization

- Superior Thermal Performance: Excellent weather and heat insulation resistance

- Reliable Traction: Caterpillar haul-off delivers stable production

- Exceptional Resistance: Fire and corrosion resistant to acids and alkalis

Main Technical Parameter

| Extruder Model | Output | Installed Power | Dimensions (LxWxH) | Product Thickness | Price |

| SJZ80/156 & SJZ51/105 | 300 – 400KG/H | 250KW | 24m*3m*3.5m | 2.0 – 3.5mm | USD 84K, FOB Shanghai |

| SJZ80/156 & JWS50/30 | 300 – 400KG/H | 250KW | 24m*3m*3.5m | 2.0 – 3.5mm | USD 97K, FOB Shanghai |

| SJZ92/188 & JWS65/30 | 400 – 600KG/H | 250KW | 24m*3m*3.5m | 2.0 – 3.5mm | USD 125K, FOB Shanghai |

Application Scenarios

Product Description

Our advanced extrusion line produces high-quality PVC roofing tiles with superior durability and weather resistance. This system combines precision engineering with excellent thermal and fire performance.

Key Features

- Precise Temperature Control: The specially designed SJZ92 conical twin-screw extruder works with imported temperature control instruments. This ensures precise temperature management and even material plasticization.

- Excellent Heat Insulation: The tiles use special technology to withstand outdoor weather and sunlight. They provide superior heat insulation and create a comfortable environment in hot summer conditions compared to metal roofing.

- Stable Traction System: The extrusion line features a caterpillar haul-off unit with a precision reduction motor and frequency converter. This delivers reasonable structure and stable traction throughout production.

- Outstanding Fire and Chemical Resistance: The tiles have remarkable fire-protection performance and are difficult to burn. They also resist corrosion, acids, and alkalis.