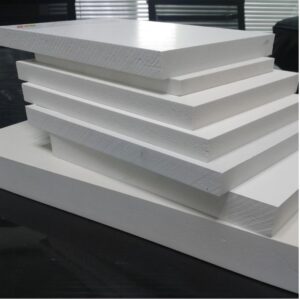

PVC Skinning (WPC) Foam Board Extrusion Line

Key Selling Points

- Maximum Productivity: SJZ80/156 extruder achieves approximately 500 kg per hour output

- Efficient Cooling: Special mold steel calibration plate provides rigidity and rapid sheet cooling

- Proven Reliability: ABB motor inverter ensures stable operation and reduces maintenance costs

- User-Friendly: High automation with simple operation ideal for modern manufacturing

Main Technical Parameter

| Extruder Model | Output | Installed Power | Dimensions (LxWxH) | Product Thickness | Price |

| SJZ80/156 | 300 – 450KG/H | 185KW | 25m*3.8m*2.5m | 5.0 – 30mm | USD 125K, FOB Shanghai |

Application Scenarios

Product Description

Our high-capacity extrusion line delivers efficient, large-scale PVC plastic sheet production. This system combines exceptional output with reliability and ease of operation.

Key Features

- High-Output Production: The SJZ80/156 extruder model achieves approximately 500 kg per hour. This ensures maximum productivity for your manufacturing needs.

- Superior Cooling System: The calibration plate is made from special mold steel with sufficient thickness. It provides rigidity and enables efficient cooling and crusting of plastic sheets.

- Stable, Reliable Operation: The equipment features an ABB brand motor inverter. This ensures stable operation and long-term reliability. It also reduces equipment failure risk and lowers maintenance costs and downtime.

- High Automation: The entire extrusion line features high automation and easy operation. This makes it ideal for market promotion and modern manufacturing environments.