- High-Speed & Energy Efficient: 35% energy savings, double production efficiency

- Optimized Extrusion Screw (38-40 L/D): Superior melt output & plasticization

- High-Torque, High-Strength Gearbox: Stable & reliable continuous operation

- Fully Integrated Smart Control: Advanced tooling, gravimetric control, servo-driven downstream

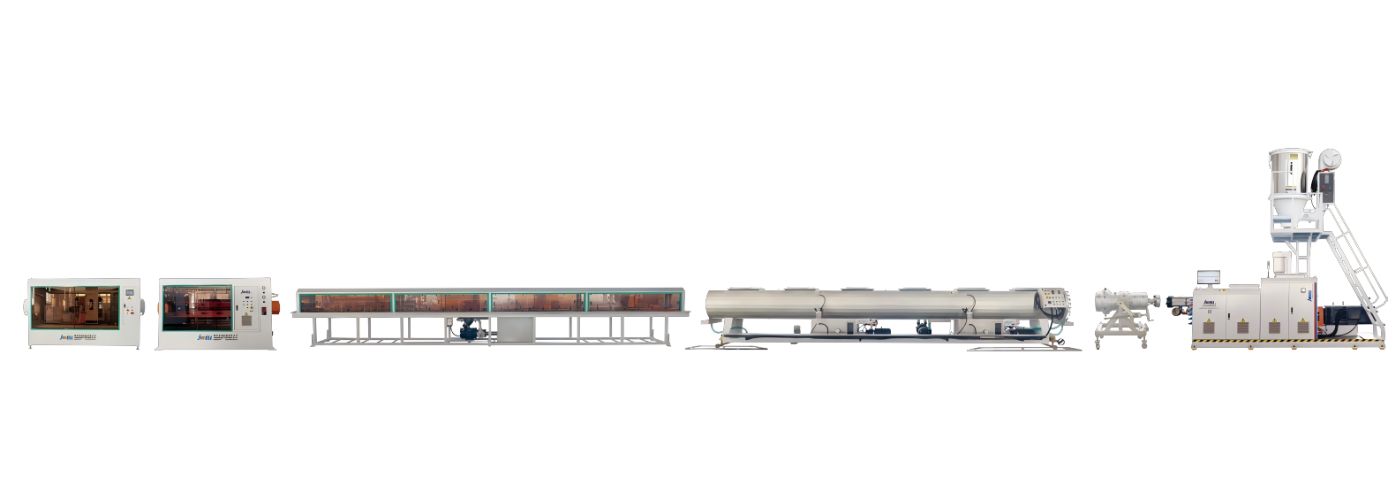

High-speed Energy-saving HDPE Solid Wall Pipe Extrusion Line

Key Selling Points

Main Technical Parameter

| Raw Material | Extruder Model | Output | Type | Installed power | Dimensions (LxWxH) | Pipe I.D. | Price / $ |

| PE | JWS-H60/40 | 350KG/H | JWPEG-H63 | 200KW – 700KW | 30mx3mx3m – 70mx5mx10m |

16 – 63mm

|

USD 56K – 134K, FOB Shanghai |

| PE | JWS-H60/40 | 450KG/H | JWPEG-H110 | 200KW – 700KW | 30mx3mx3m – 70mx5mx10m | 20 – 110mm | USD 14K – 697K, FOB Shanghai |

| PE | JWS-H75/38 | 500KG/H | JWPEG-H160 | 200KW – 700KW | 30mx3mx3m – 70mx5mx10m | 50 – 160mm | USD 14K – 697K, FOB Shanghai |

| PE | JWS-H75/38 | 550KG/H | JWPEG-H250 | 200KW – 700KW | 30mx3mx3m – 70mx5mx10m | 75 – 250mm | USD 14K – 697K, FOB Shanghai |

| PE | JWS-H75/38 | 650KG/H | JWPEG-H315 | 200KW – 700KW | 30mx3mx3m – 70mx5mx10m | 110 – 315mm | USD 14K – 697K, FOB Shanghai |

| PE | JWS-H90/38 | 950KG/H | JWPEG-H450 | 200KW – 700KW | 30mx3mx3m – 70mx5mx10m | 160 – 450mm | USD 14K – 697K, FOB Shanghai |

| PE | JWS-H90/38 | 1050KG/H | JWPEG-H630 | 200KW – 700KW | 30mx3mx3m – 70mx5mx10m | 315 – 630mm | USD 14K – 697K, FOB Shanghai |

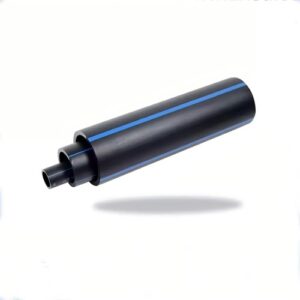

Application Scenarios

Product Description

The JWELL High-Speed Polyolefin PE Pipe Extrusion Line is an energy-efficient manufacturing system engineered for rapid production of polyethylene pipes across diverse diameter specifications.

- Next-Generation Pipe Production: A state-of-the-art extrusion line for high-speed manufacturing of polyolefin pipes, engineered for a 35% reduction in energy consumption while doubling production efficiency.

- Superior Melt & Plasticizing Performance: Features a specially designed screw with a high length-to-diameter ratio (38-40 L/D) and an optimized feeding-zone barrel, significantly improving both melt extrusion volume and plasticizing quality.

- Robust & Stable Mechanics: The system is built with a high-torque, high-strength gearbox that ensures exceptionally stable and reliable operation, even under demanding continuous production schedules.

- Precision Automated Downstream: Incorporates advanced extrusion molds and sizing sleeves, a PLC-controlled vacuum cooling tank, a servo-driven multi-track haul-off, a high-speed chipless cutter, and a precise gravimetric control system for unmatched accuracy and efficiency.