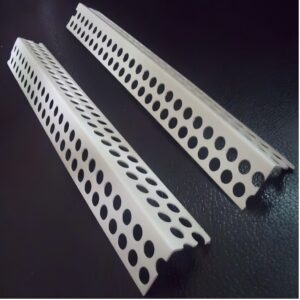

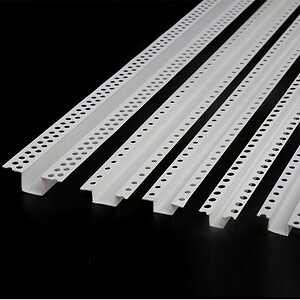

PVC A Four Yin and Yang Angle Online Punching Production Line

Key Selling Points

- One-Step Operation: Integrated punching reduces labor costs and eliminates extra steps

- Consistent Quality: Twin-screw extruder ensures full plasticization and uniform mixing

- Flexible Manufacturing: Online adjustment enables various specifications with minimal waste

- Accurate Dimensions: PLC control system maintains stable production and precise measurements

Main Technical Parameter

| Extruder Model | Output | Installed Power | Dimensions (LxWxH) | Product Thickness | Price |

| SJZ51/105 | 60-100KG/H | 66KW | 16m*2.8m*2.4m | 1.0-1.2mm | USD 32K, FOB Shanghai |

| SJZ65/132 | 100-200KG/H | 85KW | 16m*2.8m*2.4m | 1.0-1.2mm | USD 39K, FOB Shanghai |

Application Scenarios

Product Description

Our advanced extrusion line delivers high-quality PVC corner bead production with superior efficiency and flexibility. Designed for modern manufacturing demands, this system combines cutting-edge technology with practical functionality.

Key Features

- Integrated Online Punching: The built-in punching function completes the entire process in one operation. It eliminates additional steps and reduces labor costs while boosting production efficiency.

- Superior Quality Output: The parallel counter-rotation or conical twin-screw extruder features specially designed screws. These ensure complete plasticization and uniform mixing of PVC powder. The result is consistent, high-quality products with excellent physical properties.

- Production Flexibility: Adjust the production process online to manufacture corner beads of various specifications and models. This minimizes material waste and downtime when switching between product types.

- Precision Control: An advanced PLC control system maintains stable production. It ensures dimensional accuracy throughout the manufacturing process.