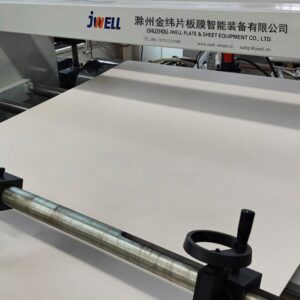

ABS, HIPS, Refrigerator Plate Extrusion Line

Key Selling Points

- High-Efficiency, Energy-Saving Extrusion: Advanced screw and temp control, output up to 1200–1500 Kg/h

- Premium ABS/HIPS/PMMA Sheet Quality: High-strength ABS, easy-forming HIPS, high-gloss transparent PMMA

- Automated, Intelligent Operation: Central auto feeding, closed-loop pressure–speed, servo roll gap, robotic stacking

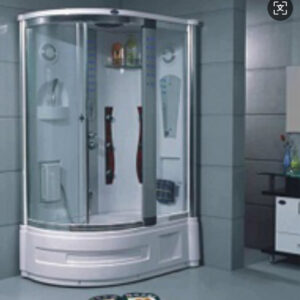

- Wide Application for Appliances & Sanitary Ware: Refrigerator liners, sanitary ware, luggage, automotive interiors

- Professional, Customized Turnkey Support: Line planning, installation, commissioning, full after-sales and technical service

Main Technical Parameter

| Extruder Model | Output | Installed Power | Dimensions (LxWxH) | Product Thickness | Price | Product width |

| JW160/60-2200 | 1500KG/H | 725KW | 41m*6m*4m | 1-6mm | USD 340-390K, FOB Shanghai | 2000mm |

| JW130/60-2000 | 1200KG/H | 585KW | 39m*6m*4m | 1-6mm | USD 250-280K, FOB Shanghai | 1800mm |

| JW120/60/45-1900 | 550KG/H | 545KW | 30m*7m*4m | 1-6mm | USD 230-250K, FOB Shanghai | 1700mm |

| JWS130+65 | 700KG/H | 560KW | 31m*7m*5m | 1-6mm | USD 200-230K, FOB Shanghai | 1800mm |

| JWS120+65 | 550KG/H | 520KW | 30m*7m*4m | 1-6mm | USD 200-230K, FOB Shanghai | 1800mm |

Application Scenarios

Product Description

High-capacity system for premium sheet manufacturing with intelligent automation. Delivers up to 1500 kg/h output for high-strength ABS, easy-forming HIPS, and high-gloss PMMA sheets used in appliances, sanitary ware, and automotive interiors.

- Efficient Energy-Saving Production: Advanced screw design and precision temperature control enable a massive 1500 kg/h output with low energy consumption and reduced unit costs

- Superior Multi-Material Quality: Produces high-strength ABS, processable HIPS, and high-gloss PMMA sheets with uniform thickness and flatness for demanding quality standards

- Intelligent Full Automation: Features closed-loop pressure control, auto-adjusting servo rolls, and robotic stacking to minimize manual labor and maximize operational consistency

- Versatile Industrial Applications: Ideal for refrigerator liners, bathtubs, luggage, and automotive components, meeting diverse manufacturing needs across multiple sectors

- Professional Customized Service: End-to-end support including tailored planning, expert installation, commissioning, and comprehensive lifetime technical maintenance