LVT Composite Floor Production Line

Key Selling Points

- Multi-Layer Precision Coextrusion: Coperion system, 4–6 layer sync, ±0.02mm layer accuracy, patented melt distribution

- 3D High-Definition Digital Printing: Rototek 2400dpi, 1000+ wood/stone patterns, UV curing, 3× wear resistance, EN13329 certified

- Intelligent Embossing Synchronization: Kurz laser-engraved rollers, 100% pattern alignment, 0.1–0.8mm depth adjustment, 20 embossing units

- End-to-End Digital Control: MES 4.0, 200+ real-time parameters, X-ray thickness scanning, ±0.05mm tolerance

Main Technical Parameter

| Extruder Model | Output | Installed Power | Dimensions (LxWxH) | Product Thickness | Price | Product width |

| SJZ80/156 | 500KG/H | 350KW | 26.5m*5.5m | 1.5-4mm | USD 120-160K, FOB Shanghai | 960mm |

Application Scenarios

Product Description

The SJZ80/156 Decorative Film Extrusion & Printing Line is a cutting-edge manufacturing system designed for premium production of high-definition printed and embossed plastic films. Combining multi-layer precision coextrusion, advanced digital printing, and intelligent embossing technology, this system delivers exceptional aesthetics and durability for decorative applications across multiple industries.

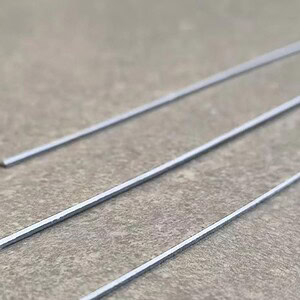

- Ultra-Precision Multi-Layer Coextrusion: Coperion extrusion system with patented melt distribution achieves ±0.02mm layer accuracy, ensuring consistent material properties and superior structural integrity across all film layers.

- High-Definition Digital Printing: Rototek printing technology delivers 2400dpi resolution with integrated UV curing, producing vibrant, detailed graphics that pass rigorous EN13329 durability standards for long-lasting color fastness.

- Intelligent Pattern Embossing: Kurz laser-engraved rollers provide 100% pattern alignment with customizable 0.1–0.8mm embossing depth, creating tactile, dimensionally accurate surface textures synchronized perfectly with printed designs.

- Advanced Digital Manufacturing Control: MES 4.0 system with real-time X-ray scanning guarantees ±0.05mm thickness tolerance, ensuring consistent quality, minimal waste, and maximum product reliability.