- Affordable Entry Point: Lower purchase cost than fully automatic lines enables quick ROI for startups

- Quick Product Switching: Change molds easily for padding, food containers, egg trays, and cup holders

- Easy Training: Streamlined processes require minimal skilled labor and quick worker training

Semi-Automatic Pulp Molding Industrial Packaging Production Equipment

Key Selling Points

Main Technical Parameter

| Parameters | |

|---|---|

| Outer Dimension (LxWxH) | 3.1m*2.16m*3.8m |

| Platen size | 800*600mm (customizable) |

| Equipment weight | 2.0T |

| Forming method | Reciprocating |

| Max. product height | 80-100mm |

| Pulp feeding style | Continuous supply of slurry |

| Drying method | Drying outside the mold |

| Product transfer method | Wet embryo transfer method |

| Power mode | Cylinder |

| Material receiving method | Pneumatic lifting platform |

| Number of work stations | 2 positions |

| Capacity | Related to product shape and labor efficiency |

| Cycle time | 8-16 seconds/drop |

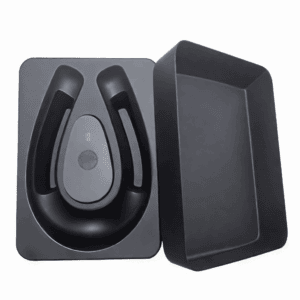

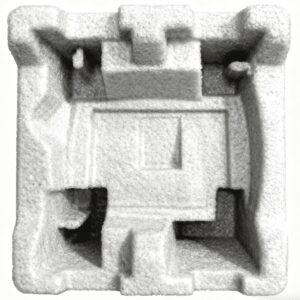

Application Scenarios

Product Description

Our semi-automatic pulp molding machine offers an affordable entry into sustainable packaging production. This system combines low investment costs with high flexibility to support diverse product requirements and rapid market response.

Key Features

- Low Investment & Fast ROI: The equipment has significantly lower purchase cost compared to fully automatic production lines. This greatly reduces financial barriers for startups and expansion while enabling rapid payback period through eco-friendly product value.

- High Production Flexibility: The machine is ideal for small batches and high-mix production. Products can be quickly switched by changing molds for industrial padding, food containers, egg trays, and cup holders.

- Simple Operation: The streamlined operational processes require less skilled labor. Workers can be trained quickly, solving the challenge of hiring highly specialized technicians.