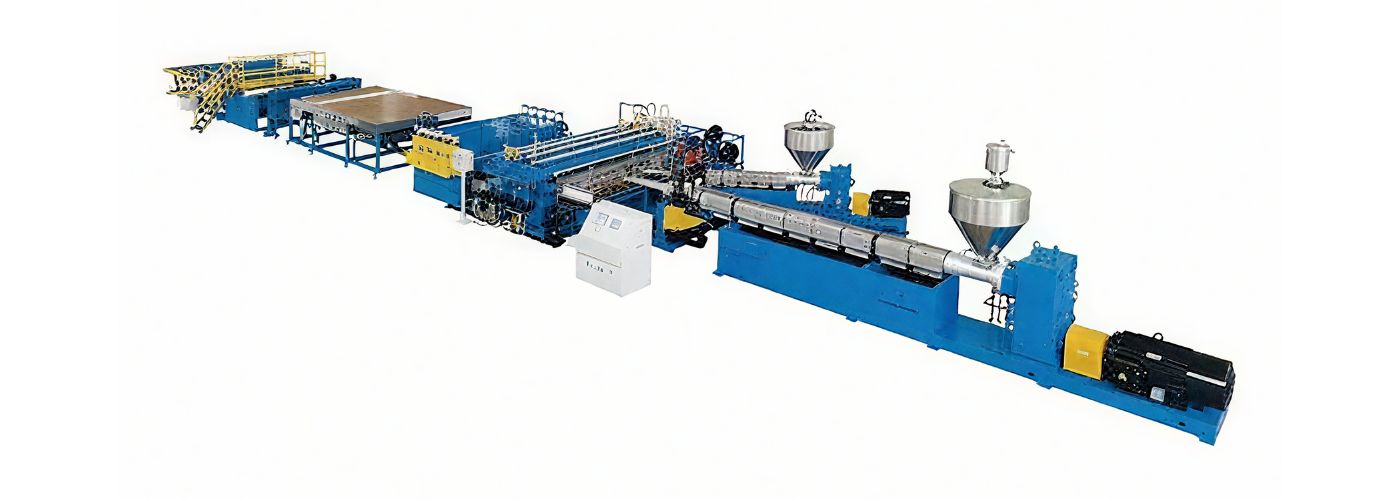

PP, PE Plastic Hollow Cross Section Plate Extrusion Line

Key Selling Points

- German-Engineered Precision Extrusion: KraussMaffei-based extruder with ±0.5% stability & patented 3-stage filtration

- Intelligent Multi-Layer Coextrusion: Aerospace-grade die with AI thickness control ensures ±0.03mm precision

- End-to-End Digital Monitoring: JWELL Cloud 4.0 enables real-time monitoring & 30-min remote troubleshooting

- Modular Flexible Production: 45-min mold change & optional ultrasonic recycling, 99.2% material usage

Main Technical Parameter

| Extruder Model | Output | Installed Power | Dimensions (LxWxH) | Product Thickness | Price | Product width |

| Ø150+75 | 500KG/H | 710K | 30m* 6m*3.2m | 2-16mm | USD 250K – 280K, FOB Shanghai | 2200mm |

| Ø120 | 350KG/H | 332KW | 25m*5.6m*4m | 2-5mm | USD 180K – 190K, FOB Shanghai | 1220mm |

| 0130 | 500KG/H | 495KW | 32m*7.2m*4.3m | 3-5mm | USD 190K – 210K, FOB Shanghai | 2700mm |

| 0150 | 450KG/H | 580KW | 30m*7m*3m | 2-4mm | USD 230K – 250K, FOB Shanghai | 2100mm |

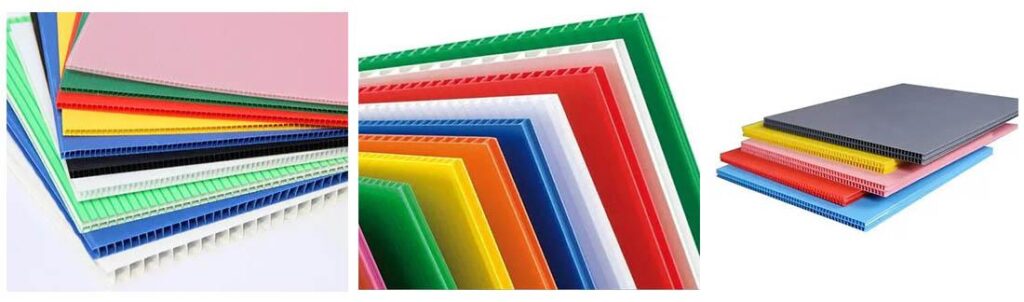

Application Scenarios

Product Description

Cutting-edge precision extrusion system combining German engineering, intelligent multi-layer technology, and digital IoT connectivity for ultra-high-precision sheet manufacturing with exceptional material efficiency.

- High-Output Line Options: Multiple models from about 350 to 500 Kg/h with widths up to 2700 mm and thickness ranges from 2 to 16 mm, covering mid to large sheet applications.

- Robust Power & Compact Layout: Installed power from roughly 332 to 710 KW with optimized line lengths between 25 and 32 m for continuous industrial operation.

- Precision Sheet Manufacturing: Multi-layer coextrusion and fine thickness control aimed at demanding applications that require stable dimensions and surface quality.

- Smart Factory Integration: Digital monitoring and fast remote service reduce downtime and support long-term, efficient production management.