PP Hollow Building Formwork Double Out Extrusion Line

Key Selling Points

- High-Efficiency Dual-Mold Output: Patented parallel flow, 2 panels/cycle, 2000㎡ daily output, 100% productivity boost

- Military-Grade Structural Strength: 5-layer coextrusion, ≥25MPa compression, adjustable honeycomb density (6×6/8×8)

- Intelligent Energy-Saving Control: 24-zone PID, ±0.8℃precision, 40% total energy reduction, waste heat recovery

- Fully Automated Digital QC: 3D laser + AI vision, ±0.1mm thickness, ≤0.5mm/m flatness, ≥99.3% yield

Main Technical Parameter

| Extruder Model | Output | Installed Power | Dimensions (LxWxH) | Product Thickness | Price | Product width |

| JWS130+80 | 450-500KG/H | 415KW | 29m* 5m*3.1m | 15-17mm | USD 180K – 200K, FOB Shanghai | 915*1mm |

| JWS150+80 | 550-600KG/H | 450KW | 30m*5m*3.1m | 15-17mm | USD 200K – 220K, FOB Shanghai | 915*2mm |

| CJWH85+52 | 600-700KG/H | 440KW | 25m*6.5m*3.1m | 15-17mm | USD 230K – 270K, FOB Shanghai | 915*2mm |

Application Scenarios

Product Description

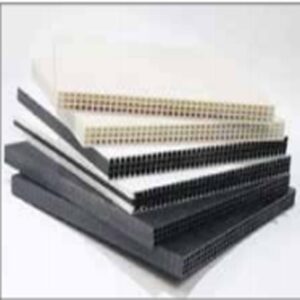

The JWS & CJWH Hollow Board Extrusion Line Series represents the pinnacle of high-performance plastic sheet manufacturing technology. Engineered for maximum productivity and superior material properties, these systems deliver industrial-scale production with precision quality control, making them ideal for packaging, construction, and specialty applications.

- Dual-Mold Parallel Production: Patented parallel flow technology enables simultaneous extrusion of two panels (1200×2400mm), achieving exceptional 2000㎡ daily output and effectively doubling productivity.

- Military-Grade Structural Integrity: 5-layer coextrusion with reinforced ribs delivers 25MPa compressive strength and customizable honeycomb density, ensuring robust panels suitable for demanding applications.

- Advanced Energy Management: 24-zone PID temperature control with integrated waste heat recycling achieves 40% energy consumption reduction, significantly lowering operational costs.

- Precision Quality Assurance: Fully automated 3D laser scanning combined with AI-driven inspection guarantees 99.3% yield rate with ±0.1mm thickness accuracy, exceeding industry standards.