PVC Floor Leather Extrusion Line

Key Selling Points

- 500-750kg/h Output: Optimized screw design achieves double-layer and three-layer production with reduced unit costs

- Durable Material: Wear-resistant, corrosion-resistant, skid-proof, and flame-retardant PVC for multiple applications

- Customizable Layers: Single or multi-layer configurations with optional unreeling and non-woven fabric combinations

- Thermal Precision: ±1℃ temperature control with coat-hanger die ensures uniform thickness and flatness

- Complete Support: Professional installation, training, and after-sales maintenance for seamless operation

Main Technical Parameter

| Extruder Model | Output | Power on | Dimensions (LxWxH) | Product Thickness | Price | Product width |

| SJZ65/132-SJZ80/156 | 500-550KG/H | 350kw | 25m*11m*4.7m | 0.5-3mm | USD 180K – 200K, FOB Shanghai | 2000mm |

| SJZ80/156-SJZ80/156 | 600-750KG/H | 350kw | 25m*11m*4.7m | 0.5-3mm | USD 190K – 210K, FOB Shanghai | 2000mm |

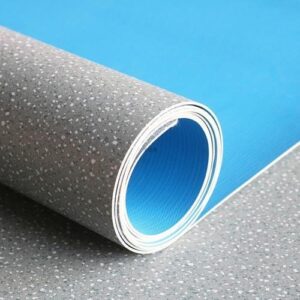

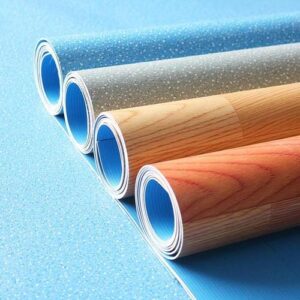

Application Scenarios

Product Description

Our high-efficiency PVC floor leather production line delivers superior quality and versatile production capabilities. This system combines precision temperature control with optimized screw design to produce durable, wear-resistant flooring for automotive, hospitality, and residential applications.

Key Features

- High-Efficiency Production Capacity: The optimized screw design and temperature control system ensure stable, efficient operation. Double-layer lines reach 500-550kg/h while three-layer lines achieve 600-750kg/h, meeting large-scale production needs and reducing unit costs.

- High-Quality Product Features: The PVC floor leather is wear-resistant, corrosion-resistant, skid-proof, and flame-retardant. It features uniform thickness, flat surface, and long-lasting colors for automotive, hotel, and residential applications.

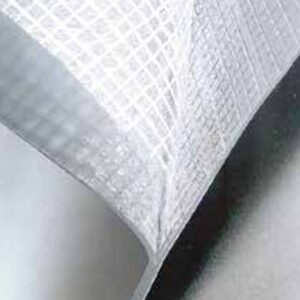

- Versatile Production Configuration: The line can be customized into single-layer or multi-layer composite production lines. An unreeling device can be added to produce inner-strengthened products or combinations with non-woven fabrics and PVC decorative films.

- Precise Process Control: Temperature control is accurate to ±1℃. The coat-hanger-type die features special double-throttling design to ensure uniform plasticization and precise thickness and flatness control.

- Professional Service Support: Jwell’s professional team provides customized solutions including installation, commissioning, employee training, and after-sales maintenance for smooth operation.