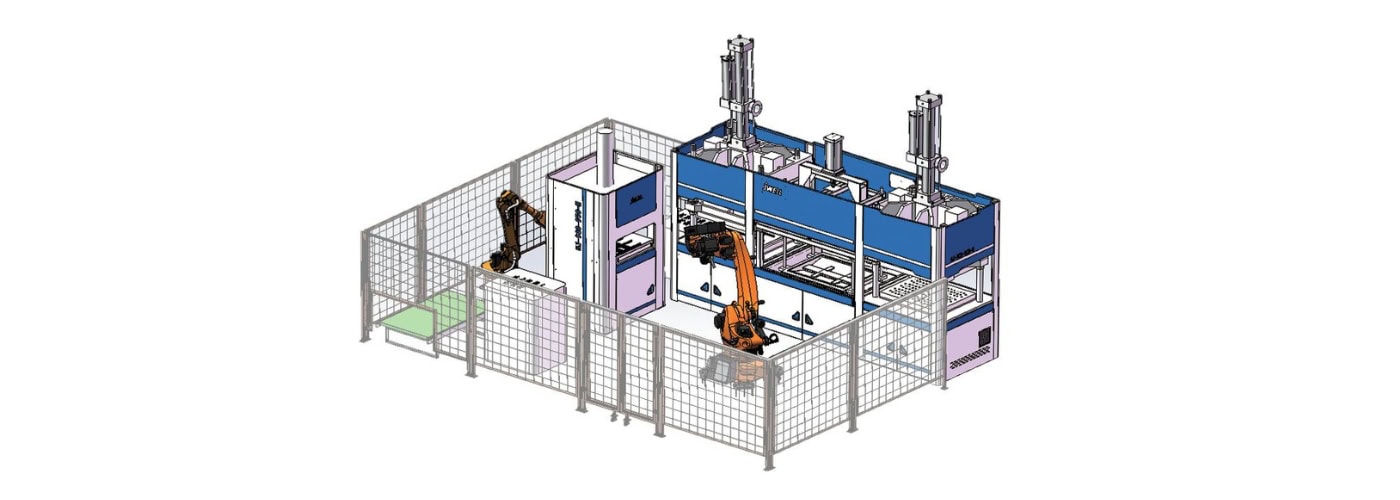

Full-Automatic Pulp Molding Premium Meal Kit Production Line

Key Selling Points

- 50% Faster Production: Automated pulping, molding, drying, and cutting achieve thousands of sets per shift

- Sustainable Materials: Bagasse and reed pulp produce naturally degradable and recyclable meal kits

- Precision Accuracy: Servo drive and mold system deliver ±0.1mm accuracy with smooth edges and clear textures

- Rapid Mold Switching: Change molds in under 30 minutes for 60-300mm kits in various compartment configurations

Main Technical Parameter

| Machine Model | Plate Size | Heating method | Forming pressure | Product Height | Cycle time |

| HJ-9895 | 980*950mm | Electricity and oil are optional | 47T | 80mm | 22-40s |

| HJ-120120 | 1200*1200mm | Electricity and oil are optional | 60T | 80mm | 22-40s |

Application Scenarios

Product Description

Our advanced automated production line manufactures high-quality, eco-friendly meal kits with full-process automation and precision control. This system delivers superior efficiency and flexibility to meet diverse market demands while supporting sustainable manufacturing practices.

Key Features

- Full-Process Automation: The line covers automatic operation of raw material pulping, molding, drying, and cutting. Manual intervention is minimized to significantly reduce labor costs. Production efficiency increases by more than 50% compared with semi-automatic lines, with single-shift capacity reaching thousands of sets.

- Eco-Friendly Material Compatibility: The system is designed specifically for pulp molding materials. It uses renewable plant fiber raw materials such as bagasse and reed pulp. The produced meal kits are naturally degradable and recyclable, complying with environmental protection packaging requirements and supporting green brand image development.

- High-Precision Molding Process: The line adopts servo drive and precision mold system. Molding accuracy reaches ±0.1mm with smooth edges without burrs, clear textures, and excellent sealing performance for soupy dishes.

- Flexible Multi-Specification Production: The system supports rapid mold change for meal kits of 60-300mm specifications with mold change time under 30 minutes. It produces single-compartment, multi-compartment, and lidded meal kits for various catering scenarios including fast food, light meals, and prepared dishes.