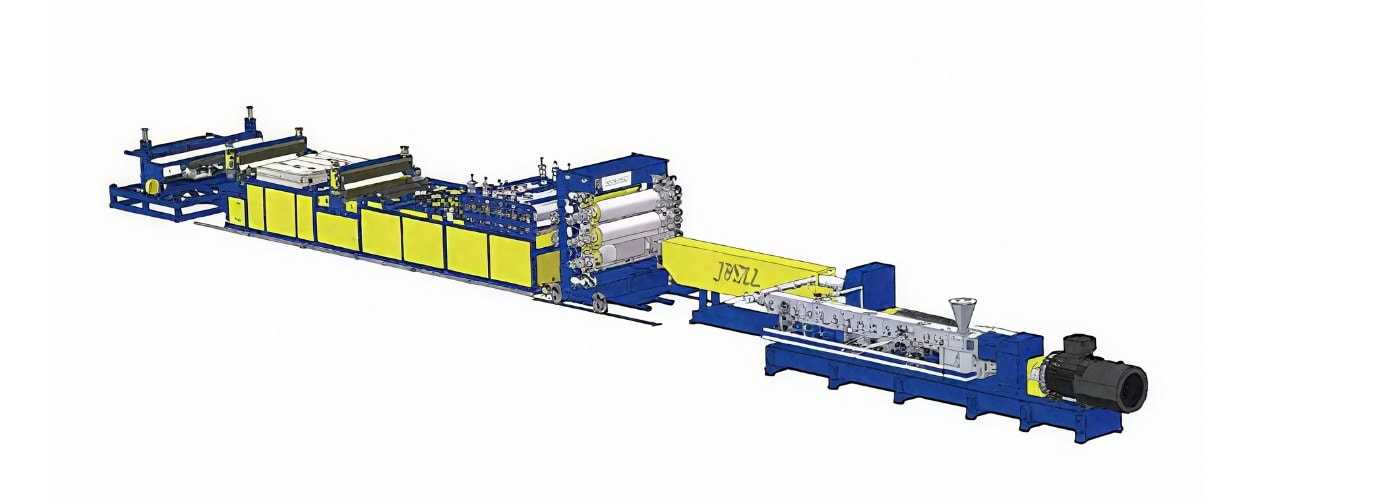

PP, PE Carbon Dioxide Supercritical Foaming Production Line

Key Selling Points

- High-Yield, Stable Throughput: 500–1000 Kg/h capacity range, long-time continuous production

- Energy-Saving, High-Torque Drive: High-torque gearbox options, performance aligned with international level

- High Automation, Low Labor Demand: Centralized weighing feeder and optional automatic packaging system

- Ceramic-Alloy Barrel Protection: Anti-corrosive, wear-resistant barrel, extended service life

Main Technical Parameter

| Extruder Model | Output | Installed Power | Dimensions (LxWxH) | Product Thickness | Price | Product width |

| JWS150/CJWH95 | 400-450KG/H | 1-5/5-20mm | USD 480-560K, FOB Shanghai | |||

| JWS130/CJWH85 | 300-350KG/H | 1-5/5-20mm | USD 340-410K, FOB Shanghai | |||

| JWS120/CJWH75 | 200-250KG/H | 1-5/5-20mm | USD 270-350K, FOB Shanghai |

Application Scenarios

Product Description

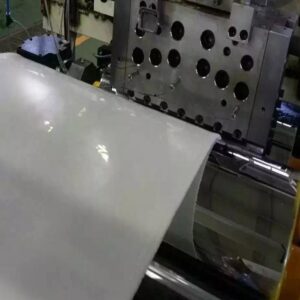

Advanced eco-friendly system for high-efficiency production of lightweight foam sheets. Features supercritical $CO_{2}$ blowing technology, precise cell structure control, and automated systems for sustainable, high-performance manufacturing.

- High-Efficiency Automated Production: Supports widths of 1000–1500mm and capacities of 200–450 kg/h with automated controls that minimize downtime and costs

- Superior Material Properties: Delivers sheets with high mechanical strength, toughness, thermal insulation, and exceptional resistance to chemicals and stress cracking

- Eco-Friendly Supercritical Technology: Uses CO2 as a foaming agent to eliminate harmful volatiles, producing fully recyclable products that meet strict environmental standards

- Advanced Foaming Control: Precision temperature and pressure regulation ensure uniform cell structure and stable, high-quality output across all runs

- Comprehensive Professional Support: Leverages 24 years of expertise to provide global 24-hour spare parts, lifetime maintenance, and end-to-end design support