Automotive

Plastic Processing Solutions for Automotive Industry

For years, JWELL has collaborated with the automotive industry to pioneer successful technologies, known for exceptional material distribution and consistent part quality.

JWELL’s advanced plastic extrusion equipment can manufacture nearly all of the plastic components in a modern car, from the largest to the smallest. We help advance the automotive industry and allow manufacturers to create components that possess high strength, low weight, and better fuel efficiency.

JWELL is more than a supplier of machinery; we are your partner for the entire product lifecycle. We are dedicated to help you use our technology to streamline your processes, boost your production, and enhance your profitability.

Applications |

|

|

Interior Parts

|

Sandwich Glass

|

|

Exterior Parts

|

Soundproof Sheets

|

|

Functional Parts

|

Composite Leather

|

|

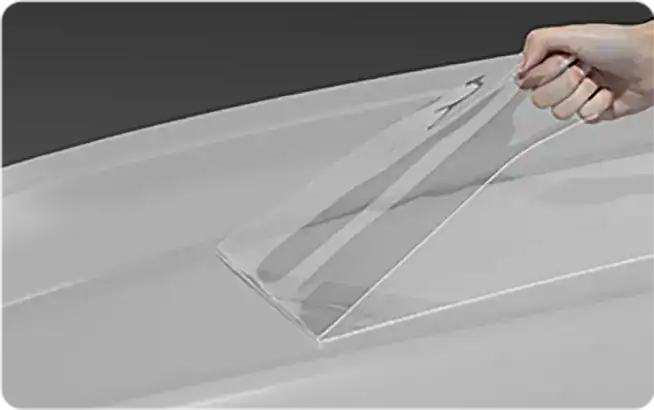

Protective Films

|

Decorative Parts

|

Featured Products

JWELL offers an extensive selection of plastic extrusion machines and professional plastic processing technologies, which provide automotive manufacturers with a competitive advantage in the market.

Sealing Profiles

Extruded rubber or plastic strips that seal doors, windows, and

Interior Parts

Functional Parts

Components engineered for specific tasks, including under-the-hood items that need to be robust and lightweight.

Protective Films

Clear, thin films applied to the car’s paint to guard against scratches, stone chips, and UV damage.

Other Industry Solutions

JWELL manufactures high-precision, melt-blown equipment for producing top-tier, breathable, non-woven fabrics. These materials are used in protective clothing for the medical, biological, and industrial sectors that meets the highest safety standards with customized solutions available.

JWELL provides advanced, energy-efficient packaging machinery. We offer high-performance solutions for producing a wide range of items like bottles, drums, and films. Our customizable and eco-friendly production lines are cost-effective and tailored to meet specific industry needs.

JWELL’s advanced plastic pipe production line leads the new building materials industry. Our high-quality pipes are lightweight, corrosion-resistant, and easy to install. Focused on sustainability, JWELL provides reliable, eco-friendly solutions for the construction sector.

JWELL provides leading plate extrusion lines for the home appliance industry, specializing in machinery for products like refrigerator plates and sanitaryware. These lines offer large output and low energy consumption, featuring automated systems for material feeding and piling. The automated production process reduces processing costs and significantly improves product quality.