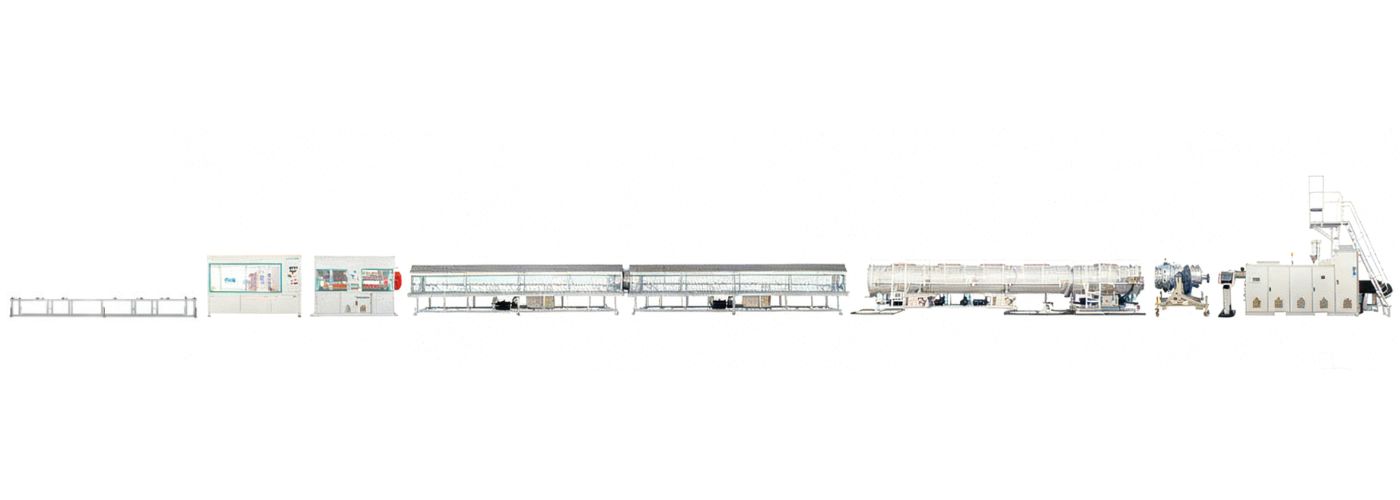

β-PPH/PVDF High-Efficiency Pipe Extrusion Production Line

Key Selling Points

- Customizable & Highly Automated: Excellent plasticizing capability

- Advanced Heat-Treated Components: Non-stick flow channel, uniform & dense extrusion

- Advanced Mold Structure: Delicate, high-gloss inner and outer pipe surfaces

Main Technical Parameter

| Raw Material | Extruder Model | Output | Type | Installed power | Dimensions (LxWxH) | Pipe I.D. | Price / $ |

| β-PPH / PVDF | 280KG/H | JWG-75 | 283KW – 696KW | 25mx2mx5m – 50mx2mx8m |

20 – 75mm

|

USD 14K – 696K, FOB Shanghai | |

| β-PPH / PVDF | 360KG/H | JWG-110 | 283KW – 696KW | 25mx2mx5m – 50mx2mx8m | 20 – 110mm | USD 14K – 696K, FOB Shanghai | |

| β-PPH / PVDF | 520KG/H | JWG-315 | 283KW – 696KW | 25mx2mx5m – 50mx2mx8m | 110 – 315mm | USD 14K – 696K, FOB Shanghai | |

| β-PPH / PVDF | 560KG/H | JWG-400 | 283KW – 696KW | 25mx2mx5m – 50mx2mx8m | 160 – 400mm | USD 14K – 696K, FOB Shanghai | |

| β-PPH / PVDF | 850KG/H | JWG-630 | 283KW – 696KW | 25mx2mx5m – 50mx2mx8m | 315 – 630mm | USD 14K – 696K, FOB Shanghai |

Application Scenarios

Product Description

The JWELL β-PPH/PVDF Corrosion-Resistant Pipe Extrusion Line is a customizable high-performance manufacturing system engineered for production of chemical-resistant pipes in polypropylene homopolymer and PVDF materials.

- Customized High-Performance Pipe Extrusion: A highly automated production line that can be customized to meet specific client needs, delivering excellent plasticizing capacity for β-PPH and PVDF materials.

- Flawless Material Flow & Density: Core components undergo an advanced heat treatment process, which prevents raw material from sticking within the flow channels, ensuring a uniform and dense material extrusion.

- Superior Surface Finish: The line is equipped with an advanced mold structure designed to produce pipes with exceptionally delicate and high-gloss inner and outer wall surfaces.