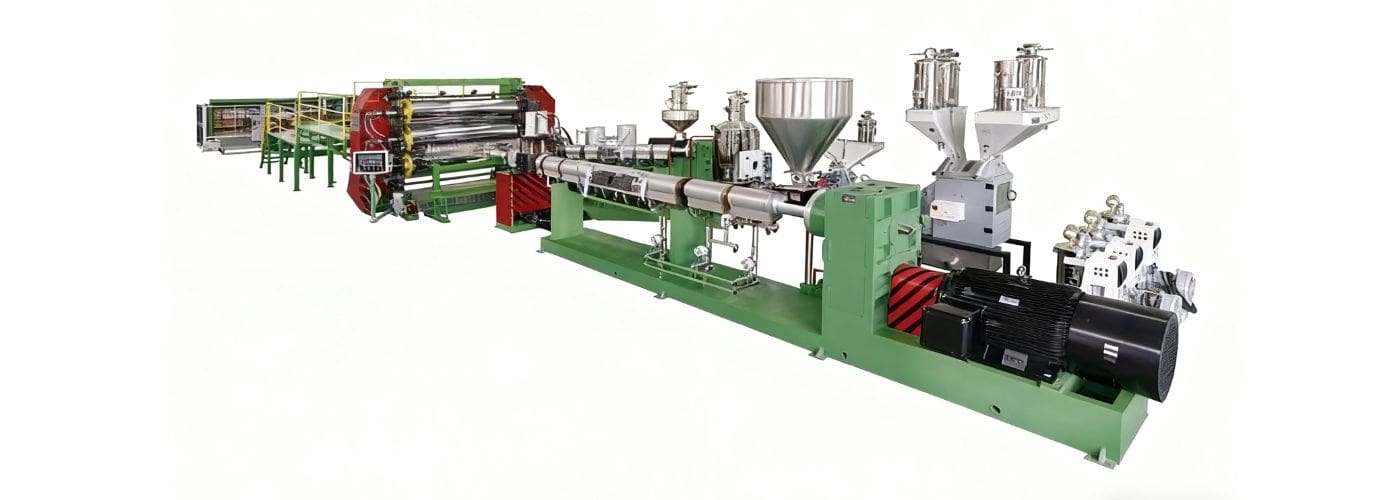

ABS/HIPS Refrigerator Sheet Production Line

Technical Specifications

The production line offers multiple models to meet different production demands. Detailed parameters are shown in the table below:

| Extruder Model | Output | Installed Power | Dimensions (L×W×H) | Product Thickness | Price (USD) | Product Width |

|---|---|---|---|---|---|---|

| JW160/60-2200 | 1500KG/H | 725KW | 41m×6m×4m | 1-6mm | 340,000 – 390,000 | 2000mm |

| JW130/60-2000 | 1200KG/H | 585KW | 39m×6m×4m | 1-6mm | 250,000 – 280,000 | 1800mm |

| JW120/60/45-1900 | 550KG/H | 545KW | 30m×7m×4m | 1-6mm | 230,000 – 250,000 | 1700mm |

| JWS130+65 | 700KG/H | 560KW | 31m×7m×5m | 1-6mm | 200,000 – 230,000 | 1800mm |

| JWS120+65 | 550KG/H | 520KW | 30m×7m×4m | 1-6mm | 200,000 – 230,000 | 1800mm |

Product Advantages

Efficient & Energy-Saving Production

Equipped with an advanced screw and precise temperature control system, the production line ensures efficient and stable operation. The maximum extrusion output can reach 1200kg/h, delivering outstanding production capacity while maintaining low energy consumption. This not only meets the needs of large-scale production but also effectively reduces the unit cost of products, enhancing your market competitiveness.

Superior Sheet Quality

The ABS, HIPS, and PMMA sheets produced by this line boast excellent performance:

- ABS sheets: High strength and strong impact resistance, suitable for durable refrigerator components.

- HIPS sheets: Easy to process and form, adapting to diverse product design requirements.

- PMMA sheets: High transparency and good surface gloss, ideal for high-aesthetic applications.

In addition, the sheets feature uniform thickness and good flatness, fully meeting the strict quality standards of industries such as refrigeration, sanitary ware, and automotive manufacturing.

Intelligent & Automated Operation

The production line integrates multiple intelligent functions to minimize manual intervention:

- Centralized automatic feeding system: Ensures accurate and stable material supply, avoiding material waste.

- Automatic closed-loop control for screw speed: Adjusts the screw speed based on real-time pressure, guaranteeing consistent discharge quality.

- Automatic gap adjustment for three-roll servo motors: Achieves precise positioning, improving the flatness of sheets.

- On-site functions: Includes online trimming, cutting, waste edge collection, and edge-free trimming. Combined with automatic robotic stacking, it significantly improves production efficiency and product consistency.

Versatile Application Compatibility

This production line has a wide range of applications, covering multiple industries:

- Home appliance industry: Production of refrigerator door liners, inner tanks, drawers, water trays, and water dispenser components.

- Sanitary ware industry: Manufacturing of bathtubs, shower rooms, steam rooms, and wash basins.

- Other fields: Production of luggage panels, automotive interior parts, etc.

It can flexibly meet the diverse product needs of different industries, providing a one-stop sheet production solution.

Professional Customized Service

Jwell Machinery’s professional team offers end-to-end customized services:

- Pre-sales: Conducts production line planning and design according to your production scale, product types, and factory layout.

- In-sales: Provides on-site installation and commissioning to ensure the production line is put into operation smoothly.

- After-sales: Offers timely maintenance support and technical guidance, ensuring the long-term stable and efficient operation of the production line.