- Fire-Rated Panels: Flame-retardant aluminum-plastic composites for premium applications

- 1800kg/h Capacity: 125% higher output reduces unit costs

- 10m/min Speed: Double traditional speed improves efficiency

- 900-1560mm Widths: Diverse specifications for curtain walls and interiors

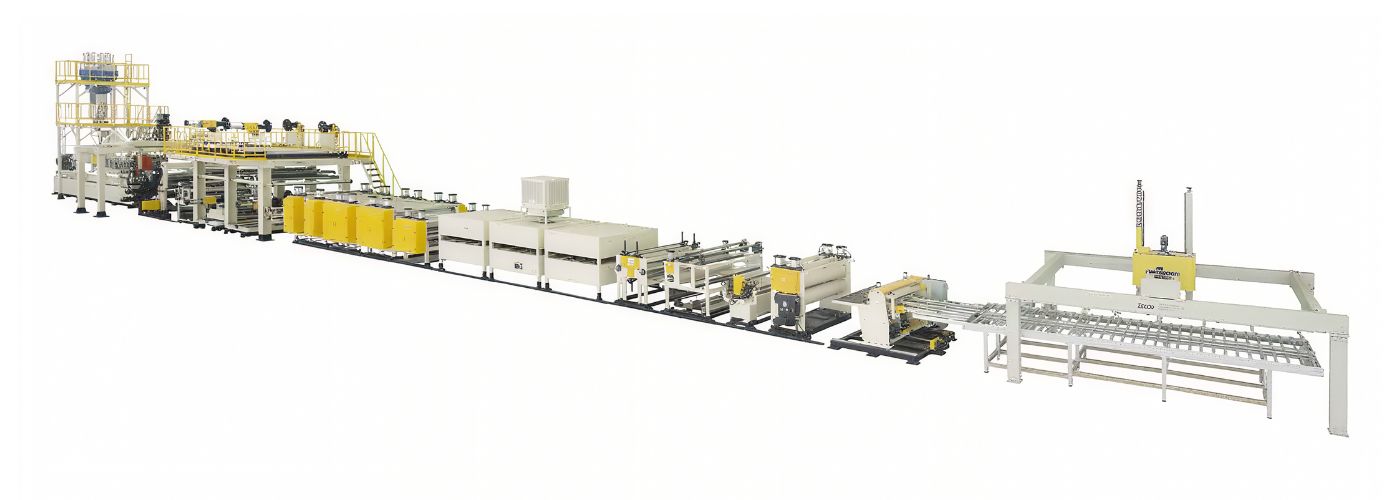

High Speed Aluminum Plastic Composite Panel Extrusion Line

Key Selling Points

Main Technical Parameter

| Extruder Model | Output | Installed Power | Dimensions (LxWxH) | Product Thickness | Price | Product width |

| JW110-44 | 1200-1500KG/H | 1090KW | 58m*9m*6.8m | 1-7mm | USD 390K, FOB Shanghai | 1220mm |

Application Scenarios

Product Description

Our high-performance aluminum-plastic composite panel extrusion line delivers efficient production of flame-retardant materials. This system combines advanced extrusion technology with high-speed production to manufacture premium panels for building curtain walls and exterior decoration applications.

Key Features

- Advanced Technology + Flame-Retardant Products: Advanced extrusion system produces high-filling flame-retardant grade aluminum-plastic composite panels. Superior fire safety performance meets core requirements for building curtain walls and exterior wall decoration in high-end applications.

- Ultra-High Output: Maximum output reaches 1800kg/h, far exceeding traditional 500-800kg/h capacity. This significantly reduces unit-time production costs and meets rapid delivery needs for large-scale orders.

- High Line Speed: Production line speed reaches 10m/min, double the traditional 5m/min speed. Shorter production cycles improve overall operation efficiency and reduce order waiting time.

- Wide Specification Coverage: Produces panels with widths from 900mm to 1560mm and aluminum foil thickness of 0.18mm and above. Diverse specifications adapt to building curtain walls, interior decoration, and advertising applications with strong product versatility.