High Speed Surface Mounted Drip Irrigation Tape Production Line

Key Selling Points

- Fully Automated Dripper Handling: Automatic feeding, screening, embedding & speed synchronization

- Advanced Extrusion & Sizing: Smooth surface finish, precise dimensions

- Precision Punching & Haul-Off: Stable servo traction, PLC-controlled mechanical punching, residue recovery

Main Technical Parameter

| Raw Material | Extruder Model | Output | Type | Installed Power | Machine Weight | Colour | Dimensions (LxWxH) | Pipe I.D | Price / $ |

| PE | JWS80 | 5000KG/H | JWG-20 | 210KW | 10T | JWELL Standard Color | 30mx10mx3m | 16 – 20mm | USD 10K – 3M, FOB Shanghai |

Application Scenarios

Product Description

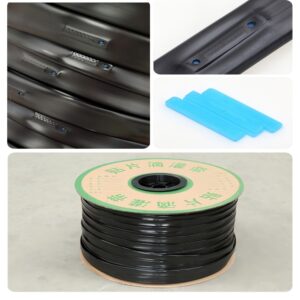

The JWELL Drip Irrigation Tape Production Line is a fully automated high-speed manufacturing system engineered for efficient production of thin-walled lightweight drip irrigation tape with integrated drip head embedding and precise hole drilling.

- Fully Automated Production: A complete system for producing thin-walled, lightweight patch drip irrigation tape. The entire process of dripper feeding, screening, conveying, storage, supply, and embedding is fully automated and synchronized with the line speed.

- Superior Tape Quality: Utilizes an advanced extruder head and a precision shaping process to ensure the final drip tape has a perfectly smooth surface and accurate, consistent dimensions.

- High-Speed, Clean Perforation: Employs a servo-driven haul-off for exceptionally stable speed control. The drip holes are created by a high-speed, PLC-controlled mechanical punching system that includes an integrated residue recovery unit, ensuring fast, clean holes with no debris.