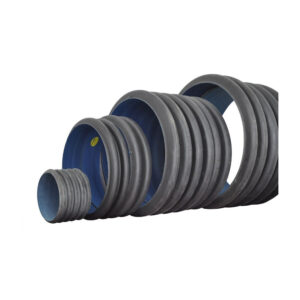

Horizontal Double Wall Corrugated Pipe Production Line

Key Selling Points

- Versatile Extruder Options: For HDPE, PP, PVC & single-wall corrugated pipes

- Optimized Ring Stiffness: Wear-resistant sizing sleeve, software-designed waveform

- Durable Forming Machine: Gear-driven base, high-load bearings, stable operation

- Quick-Change, Rapid-Cooling Modules: Universal, quick-release design with efficient internal cooling

- Advanced PLC Control System: Full line linkage, simple operation, automatic fault alarm

Main Technical Parameter

| Raw Material | Extruder Model | Output | Type | Installed power | Dimensions (LxWxH) | Pipe I.D. | Price |

| PE/PP/PVC | JWS-90/33+JWS75/33 | 600/400KG/H | JWSBG-300H | 400KW – 600KW | 12mx3mx3m – 20mx5mx5m |

100mm – 300mm |

USD 14K – 2.78M, FOB Shanghai |

| PE/PP/PVC | JWS-120/33+JWS90/33 | 800/600KG/H | JWSBG-600H | 400KW – 600KW | 12mx3mx3m – 20mx5mx5m | 200mm – 600mm | USD 14K – 2.78M, FOB Shanghai |

| PE/PP/PVC | JWS-150/33+JWS90/33 | 1300/600KG/H | JWSBG-800H | 400KW – 600KW | 12mx3mx3m – 20mx5mx5m | 200mm – 800mm | USD 14K – 2.78M, FOB Shanghai |

| PE/PP/PVC | JWS-150/33+JWS90/33 | 1300/600KG/H | JWSBG-800H | 400KW – 600KW | 12mx3mx3m – 20mx5mx5m | 300mm – 1000mm | USD 14K – 2.78M, FOB Shanghai |

| PE/PP/PVC | JWS-150/33+JWS120/33 | 1300/800KG/H | JWSBG-800H | 400KW – 600KW | 12mx3mx3m – 20mx5mx5m | 400mm – 1200mm | USD 14K – 2.78M, FOB Shanghai |

Application Scenarios

Product Description

High-capacity, modular system for HDPE, PP, and PVC pipes in solid-wall and single-wall corrugated configurations. Featuring software-optimized sizing, rapid-cooling modules, and advanced PLC control for stable, high-speed production.

- Multi-Material Versatility: Offers a variety of extruder options to produce a wide range of products, including standard HDPE, PP, and PVC pipes as well as single-wall corrugated pipes, all on one flexible platform.

- Superior Pipe Quality & Performance: Sizing sleeves are made from a durable, wear-resistant aluminum alloy. The pipe’s corrugation profile is calculated by a specialized software program to achieve optimal ring stiffness at a lower material weight.

- Robust & Stable Operation: The forming machine’s sliding base is gear-driven and equipped with large-sized needle roller bearings, enhancing its load-bearing capacity and ensuring smoother, more stable operation and a longer service life.

- Efficient & Rapid Production: Features a universal, quick-release module design for fast and convenient changeovers between different pipe specifications. A unique internal module cooling design allows for the rapid flow of water, enabling fast cooling and shaping of the pipe.