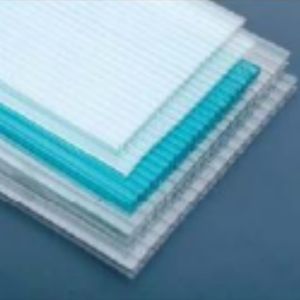

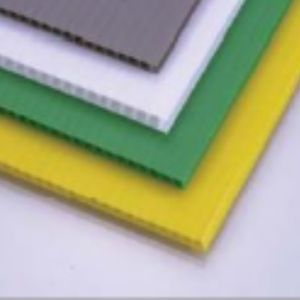

PC Plastic Hollow Cross Section Plate, Solar Panel, Flying Wing Panel Extrusion Line

Key Selling Points

- Lightweight, High-Impact Hollow Structure: Honeycomb design, over 200× glass impact resistance

- Excellent Thermal and Acoustic Insulation: Hollow cavities for low heat transfer and effective noise reduction

- UV-Stabilized, Long-Service Outdoor Durability: Weather-resistant, wide temperature tolerance, acid/alkali resistant

- Recyclable, Easy-to-Install Modular Panels: Eco-friendly material, cuttable and bendable, fast on-site installation

Main Technical Parameter

| Extruder Model | Output | Installed Power | Dimensions (LxWxH) | Product Thickness | Price | Product width |

| JWS130+45 | 400-500KG/H | 715KW | 37m*7.5m*6.5m | 4-20mm | USD 250-270K, FOB Shanghai | 2100mm |

| JWS120+45 | 300-400KG/H | 690KW | 36m*7.5m*3.6m | 4-10mm | USD 200-240K, FOB Shanghai | 2100mm |

Application Scenarios

Product Description

High-performance manufacturing system for lightweight, durable polycarbonate honeycomb sheets combining superior impact resistance, thermal/sound insulation, and weather durability.

- Superior Thermal & Sound Insulation: Air cavities effectively block heat transfer and reduce noise transmission, perfect for greenhouse panels, skylights, and acoustic barrier applications.

- Extreme Weather Resistance: UV-resistant coating prevents yellowing and cracking; temperature range of -40℃ to 120℃ ensures durability in demanding climates and seasonal variations.

- Eco-Friendly & Installation Ease: 100% recyclable polycarbonate material with modular design enables rapid cutting, simple assembly, and fast on-site installation reducing labor costs.

- Automated High-Efficiency Production: Advanced extrusion technology delivers consistent output (300–500 kg/h) with precise thickness control (4–20mm) and standard width (2100mm).