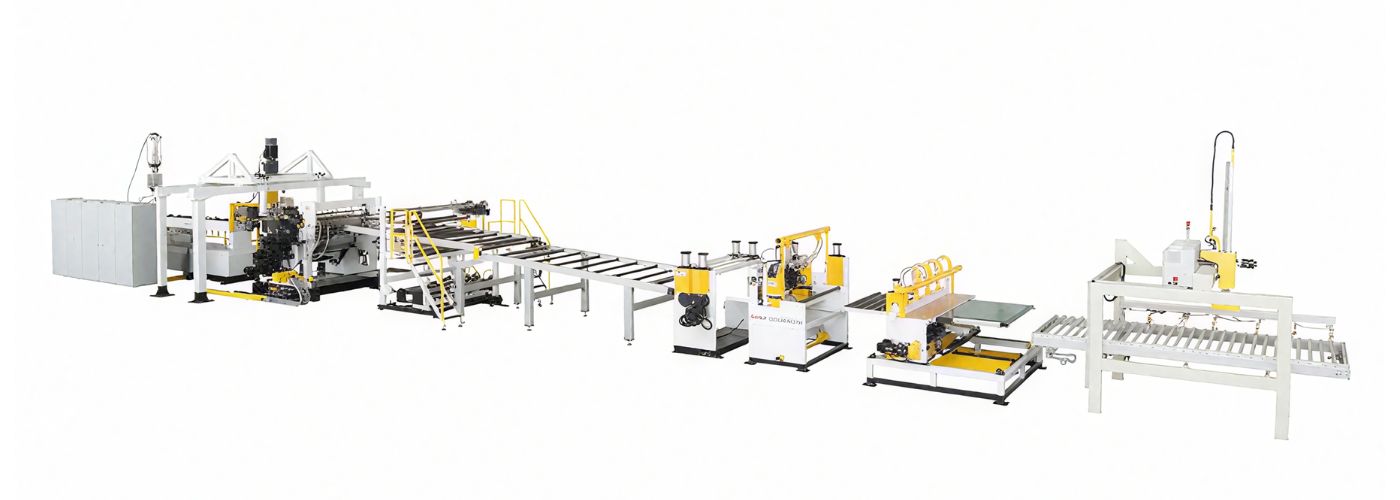

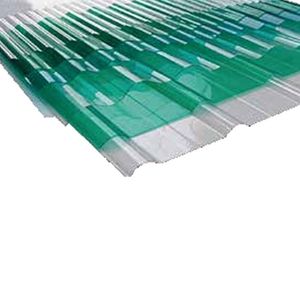

PC, PMMA, GPPS Optical Sheet, PC Sheet Extrusion Line, Corrugated Sheet Production Line

Key Selling Points

- 450-550kg/h Output: Advanced screw design meets diverse production needs

- Multi-Material Compatibility: PC, PMMA, and GPPS with flexible parameter adjustment

- Real-Time Monitoring: Precision thickness control ensures uniform quality

- Complete Support: Planning through maintenance for seamless operation

Main Technical Parameter

| Extruder Model | Output | Installed Power | Dimensions (LxWxH) | Product Thickness | Price | Product width |

| JW130 | 550KG/H | 600KW | 44m*7m*4.1m | 1.8-16mm | USD 250-300K, FOB Shanghai | 1200mm |

| JW120+45 | 450KG/H | 675KW | 34m*7m*5.1m | 1-10mm | USD 240-270K, FOB Shanghai | 1500mm |

Application Scenarios

Product Description

Our high-performance extrusion line delivers superior quality optical sheets, PC endurance boards, and corrugated tiles. This system combines advanced screw design with precise temperature control to meet large-scale production needs while reducing unit costs.

Key Features

- Efficient and Stable Extrusion: The advanced screw design and temperature control system ensure efficient and smooth production. Optical sheet output reaches [X]kg/h with considerable outputs for PC endurance boards and corrugated tiles, meeting large-scale production needs.

- Superior Product Quality:

- Optical Sheets: PC/PMMA/GPPS sheets feature high light transmittance, good light uniformity, and low haze for electronic display and lighting applications.

- PC Endurance Boards: They offer high strength and impact resistance several times greater than ordinary glass. Excellent weather resistance and thermal insulation reduce energy consumption.

- Corrugated Tiles: Lightweight and easy to install with excellent waterproof and corrosion-resistant properties for building roofs.

- Versatile Material Compatibility: The line flexibly adapts to various raw materials like PC, PMMA, and GPPS. Process parameters are accurately adjusted to meet different product characteristics and customer needs.

- Precise Process Control: High-precision thickness gauges and intelligent control system monitor and adjust sheet thickness in real-time. Optimized mold design ensures dimensional accuracy and surface flatness.

- Professional Customized Service: Jwell’s professional team provides customized solutions from production line planning and design through installation, commissioning, and after-sales maintenance for stable operation.