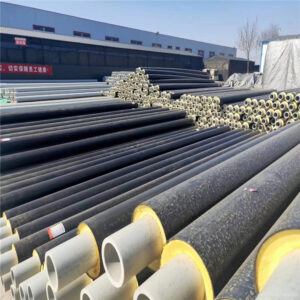

PE Insulation Pipe Extrusion Line

Key Selling Points

- Specialized PE Insulation Mold: Stable pressure, uniform thin-wall thickness

- High-Speed Extrusion: Superior output & surface brightness vs. blow-molding

- Durable Modular Cooling System: Water-jet cut stainless steel flanges, easy maintenance

- Robust Downstream Equipment: Easy-to-use haul-off, high-strength steel cutter

Main Technical Parameter

| Extruder Model | Output | Installed Power | Dimensions (LxWxH) | Pipe I.D (mm) | Price |

| JWS75/38 or JWS90/33 | 500 – 600KG/H | 260 – 632KW | 35m*3m*3m – 60m*5.5m*6m | Φ200 – Φ630 | USD 27K – 1.11M, FOB Shanghai |

| JWS90/38 or JWS90/33 | 600 – 750KG/H | 260 – 632KW | 35m*3m*3m – 60m*5.5m*6m | Φ315 – Φ960 | USD 27K – 1.11M, FOB Shanghai |

| JWS120/38 or JWS120/33 | 800 – 1000KG/H | 260 – 632KW | 35m*3m*3m – 60m*5.5m*6m | Φ760 – Φ1380 | USD 27K – 1.11M, FOB Shanghai |

| JWS120/38 or JWS150/33 | 1000 – 1100KG/H | 260 – 632KW | 35m*3m*3m – 60m*5.5m*6m | Φ1054 – Φ1680 | USD 27K – 1.11M, FOB Shanghai |

| JWS120/38 or JWS-150/33 | 1200 – 1300KG/H | 260 – 632KW | 35m*3m*3m – 60m*5.5m*6m | Φ1054 – Φ1960 | USD 27K – 1.11M, FOB Shanghai |

Application Scenarios

Product Description

JWELL’s PE insulation pipe line combines a specialized thin-wall mold for uniform thickness, high-speed extrusion (far exceeding air-blown methods), stainless-steel modular vacuum/spray cooling, optimized haul-off, and rugged high-strength cutting—delivering bright-finish pipes with minimal waste and easy maintenance.

- Specialized Extrusion for Insulation Pipes: The line is engineered with a special PE insulation pipe mold that guarantees stable extrusion pressure and results in thin-walled pipes with excellent thickness uniformity.

- High-Speed, High-Quality Output: This production line boasts a fast extrusion speed that significantly increases output compared to traditional blow-molding methods. It also produces pipes with a brighter, more finished surface and features a high degree of automation.

- Durable & Maintainable Design: The vacuum shaping and spray cooling boxes feature flanges made from water-jet cut stainless steel. Their modular design ensures long-term durability while making maintenance and parts replacement simple and convenient.

- Reliable & Efficient Downstream: A user-friendly haul-off unit effectively minimizes waste pipe generation. The cutting machine is equipped with a high-strength, durable steel structure for its feed rocker arm, ensuring long-lasting, reliable performance.