PETG Sheet Extrusion Line

Key Selling Points

- Three-Layer Structure: Precise co-extrusion delivers excellent transparency

- 30% Cost Reduction: Intelligent metering and material recycling maintain quality

- SGS Certified: Meets REACH and RoHS standards

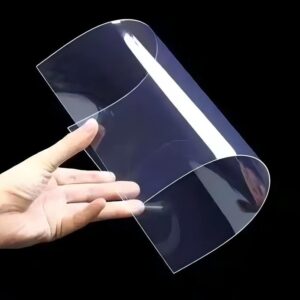

- 0.1-3mm Range: Quick customization up to 2.5 meters wide

Main Technical Parameter

| Extruder Model | Output | Installed Power | Dimensions (LxWxH) | Product Thickness | Price $ | Product width |

| CJWH85&65-1260/1500 | 800-950KG/H | 650KW | 25m*7m*5m | 0.12-1.0mm | USD 278K, FOB Shanghai | 800-1260mm |

| JWS120&65-1260/1500 | 650-700KG/H | 600KW | 25m*7m*5m | 0.12-1.0mm | USD 250K, FOB Shanghai | 800-1260mm

|

| CJWH85&65-1260/1500 | 800-950KG/H | 650KW | 25m*7m*5m | 0.12-1.0mm | USD 278K, FOB Shangha | 800-1260mm |

| JWS120&65-1260/1500 | 650-700KG/H | 600KW | 25m*7m*5m | 0.12-1.0mm | USD 250K, FOB Shanghai | 800-1260mm |

Application Scenarios

Product Description

Our high-performance PETG co-extrusion lamination line delivers precision production of multi-layer sheets. This system combines advanced co-extrusion technology with intelligent control to produce high-quality PETG sheets for premium decoration and packaging applications.

Key Features

- Precision Co-Extrusion Lamination Technology: The multi-layer co-extrusion molding process precisely controls the compounding ratio and thickness of PETG materials. This ensures uniform integration of the three-layer structure with excellent transparency and smooth texture for high-end decoration and packaging applications.

- Efficient Cost Optimization Solution: The automated intelligent control system optimizes production efficiency. Precise metering and raw material recycling technologies significantly reduce PETG usage while maintaining product quality. Comprehensive costs are reduced by 30% compared to traditional PETG sheet production, enhancing market competitiveness.

- Superior Environmental Performance Assurance: The environmentally friendly production process emits no harmful gases during operation. Finished products have obtained SGS environmental certification and meet international standards such as REACH and RoHS. This meets demand for green materials in furniture and pharmaceutical industries.

- Full-Spectrum Flexible Production: The modular design enables quick PETG sheet production with customized capabilities for building materials, packaging, and pharmaceuticals. Thickness adjustment ranges from 0.1-3mm with maximum width of 2.5 meters for efficient delivery of varied specifications.