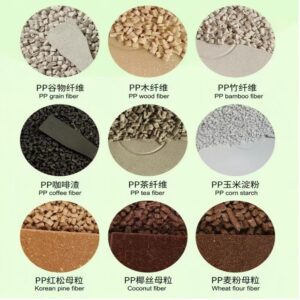

PP and Wood Powder, Bamboo Powder and Fiber Composite Sheet Extrusion Line

Key Selling Points

- Conical Twin-Screw: Domestic leading standards with excellent sheet quality

- Deep Forming: One-time hot-press compounding achieves superior quality

- Material Recycling: Reduces costs and waste sustainably

- Multi-Industry Use: Automotive, hospitality, and decoration applications

Main Technical Parameter

| Extruder Model | Output | Installed Power | Dimensions (LxWxH) | Product Thickness | Price | Product width |

| SJZ92/188 | 350-450KG/H | 183KW | 27m*6m*5m | 1-6mm | USD 236K, FOB Shanghai | 1200-1600mm |

| SJP140/25 | 500-600KG/H | 266KW | 27m*6m*5m | 2-8mm | USD 264K, FOB Shanghai | 1500-1600mm |

Application Scenarios

Product Description

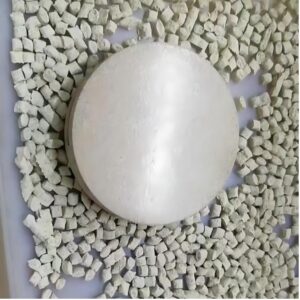

Our high-performance PP composite sheet production line delivers efficient manufacturing of premium composite materials. This system combines conical twin-screw extrusion technology with specialized processes to produce high-quality sheets for automotive and decoration applications.

Key Features

- Leading-Edge Technology Pioneering: Conical twin-screw extruder equipped with special processes achieves domestic leading technology standards. Precise process control ensures excellent sheet quality and provides a solid foundation for efficient production.

- Excellent Performance Standing Out: Composite sheets feature deep forming and deep stretching capabilities for one-time hot-press compounding with various fabrics. Superior product quality meets high-standard production requirements and handles complex process challenges effectively.

- Green Environmental Protection and Efficiency Enhancement: Leftover materials recycle through the production process. Material cost reduction and resource waste decrease support sustainable development and create economic and environmental benefits.

- Model of Diversified Applications: Widely used in high-end automotive interior parts, ceilings, and automotive fields. Also suits hotel and restaurant decoration, adapting to multiple industries and improving product competitiveness.