PS Plastic Foamed Picture Frame Extrusion Line

Key Selling Points

- Special Screw Design: Single or twin-screw extruders ensure complete plasticization and uniform mixing

- Power Efficiency: Imported AC inverter allows accurate motor adjustment and prevents energy waste

- Quality Components: Vacuum pump and gear reducer offer reliable performance and easy maintenance

- Cost-Effective Production: Good plasticization, high output, and low energy consumption

Main Technical Parameter

| Extruder Model | Output | Installed Power | Dimensions (LxWxH) | Product Thickness | Price |

| JWS65+JWS35 | 60 – 90KG/H | 106KW | 25m*2.8m*3.2m | 50 – 300mm | USD 26K, FOB Shanghai |

| JWS90+JWS45 | 100 – 150KG/H | 142KW | 25m*2.8m*3.2m | 300 – 400mm | USD 35K, FOB Shanghai |

| JWS100+JWS45 | 200 – 300KG/H | 240KW | 25m*2.8m*3.2m | 400 – 600mm | USD 42K, FOB Shanghai |

| JWS120+JWS45 | 300 – 450KG/H | 240KW | 25m*2.8m*3.2m | 600 – 800mm | USD 49K, FOB Shanghai |

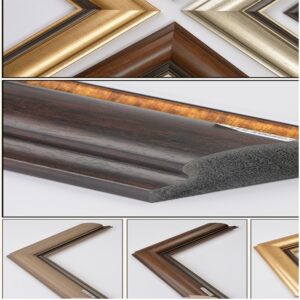

Application Scenarios

Product Description

Our advanced extrusion line produces high-quality PS plastic foam frame profiles with superior precision and flexibility. This system combines efficient manufacturing with reliable performance for large-scale production needs.

Key Features

- Precise Temperature Control: The production line is equipped with imported RKC temperature control instruments and other components. This accurately controls temperature and ensures uniform material plasticization for stable quality and reliable performance.

- High-Efficiency Production: The line features a high-efficiency single-screw main extruder with supporting co-extrusion equipment. The reasonable equipment combination and control system deliver high operating efficiency and output for large-scale production.

- Reliable Stability: The line is equipped with imported ABB AC inverters and high-quality components. This ensures reliable quality and strong stability. It reduces equipment failure rates, extends service life, and guarantees long-term stable operation.

- Advanced Hot Embossing System: The thermal transfer unit uses hot embossing method with precise hot stamping and strong adsorption force. The adjustable hand wheel can emboss various special-shaped profiles to meet diverse production needs and add rich appearance effects.