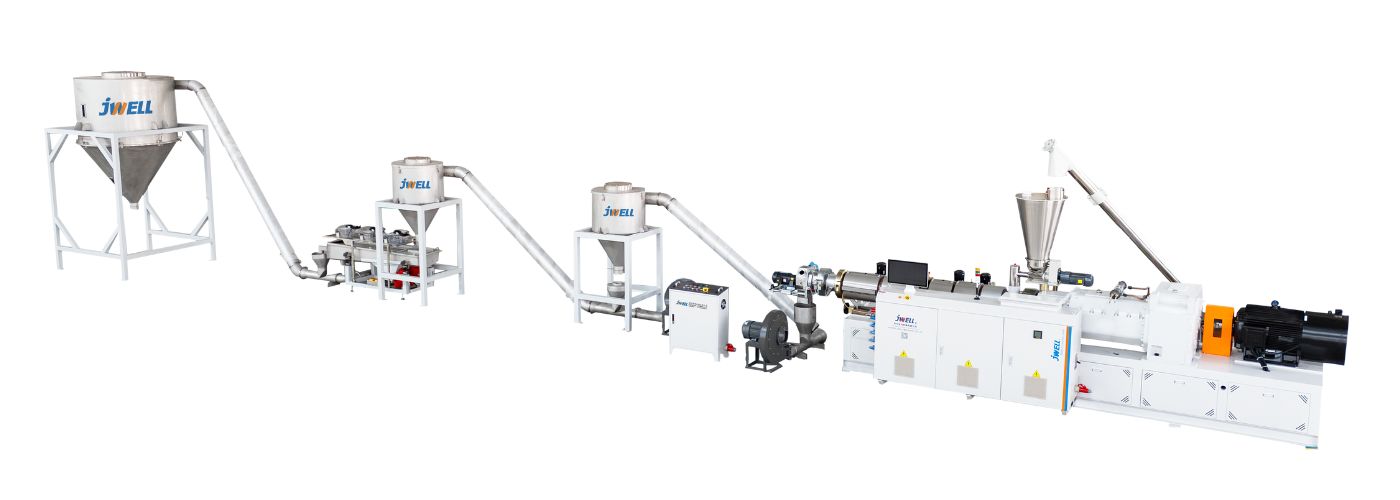

PVC Conical Twin Screw Extruder Hot-Cut Granulation Extrusion Line

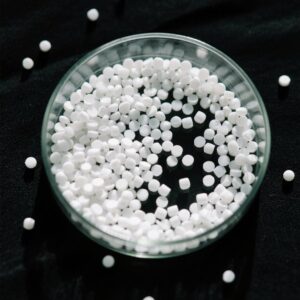

This complete pelletizing line combines a counter conical twin‑screw extruder with downstream granulation equipment to produce high‑quality PVC pellets for both soft and rigid grades. The system delivers uniform, dense and attractive pellets with high automation and strong production efficiency, ideal for large‑scale PVC pellet manufacturing.

Key Selling Points

- Versatile PVC Pelletizing: For both soft and rigid PVC, produces uniform, dense pellets

- Automated Downstream System: Die-face cutting, air transferring, vibration cooling

- High Output Capacity: 800-900 kg/h with the SJZ92/188 extruder

Main Technical Parameter

| Extruder Model | Output | Installed power | Dimensions (LxWxH) | Particle size | Price / $ |

| SJZ92/188 | 800-900 KG/H | 180KW / 220KW | 10mx2mx4m | Customizable | USD 56K – 134K, FOB Shanghai |

Application Scenarios

Product Descirption

The JWELL Plastic Pelletizing Line is a high-performance recycling and pelletizing system designed for continuous, high-volume production of uniform, premium plastic pellets.

- Complete Pelletizing Solution: This is a complete machine set composed of a conical twin-screw extruder and its corresponding downstream equipment, designed specifically for the high-efficiency pelletizing of both soft and rigid PVC materials. The resulting pellets are uniform, solid, and have an excellent appearance.

- Automated Downstream Processing: The auxiliary equipment features a die-face cutter, an air-transferring unit, and a vibration separating and cooling unit. This highly automated system ensures high production efficiency from pelletizing to final collection.

- High-Capacity Production: When equipped with the powerful SJZ92/188 conical twin-screw extruder, the line achieves a high output, capable of producing 800-900 kg of PVC pellets per hour.