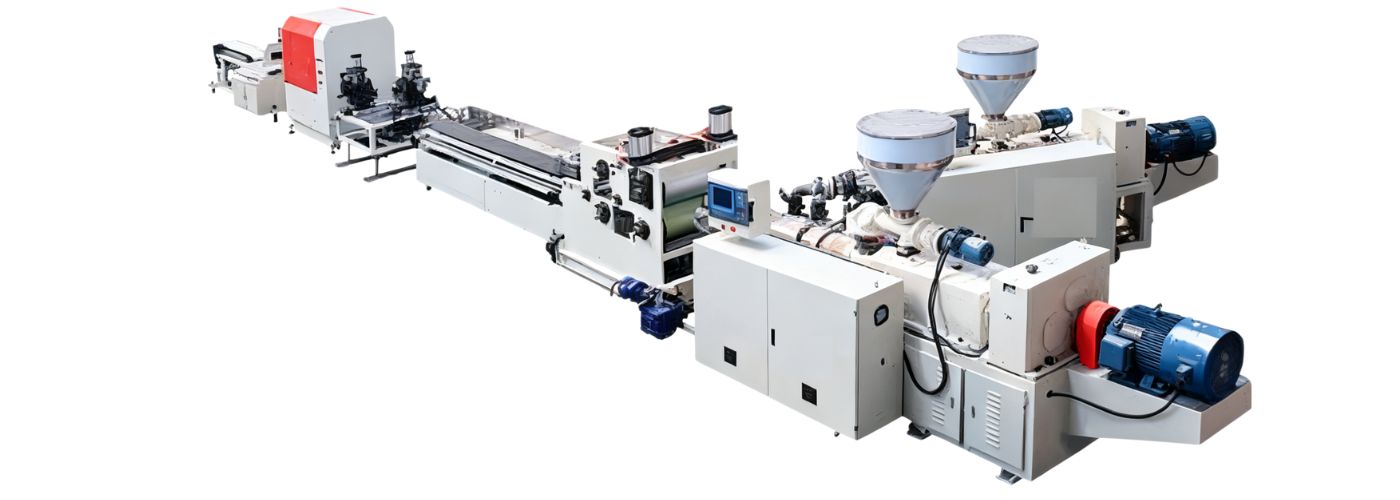

PVC / PP Siding Panel High Speed Extrusion Line

Key Selling Points

- Precision Extrusion: SJZ92 conical twin-screw extruder with imported temperature control ensures consistent quality

- Simple Maintenance: Quickly replaceable embossing roller system with long service life and easy operation

-

Integrated Punching: Online punching with optional rolling and printing capabilities

- Full Automation: PLC automatic control system enables full-process operation with real-time monitoring

Main Technical Parameter

| Extruder Model | Output | Installed Power | Dimensions (LxWxH) | Product Thickness | Price |

| SJZ65/132 | 100 – 120KG/H | 120KW | 20m*2.3m*2.4m | 0.8 – 1.2mm | USD 56K, FOB Shanghai |

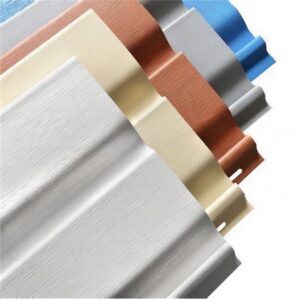

Application Scenarios

Product Description

Our advanced extrusion line produces high-quality PVC siding panels with superior precision and automation. This system combines efficient manufacturing with flexible customization options to meet diverse production needs.

Key Features

- Superior Material Plasticization: The specially designed SJZ92 conical twin-screw extruder ensures even material plasticization. Imported temperature control instruments provide accurate temperature management for consistent quality.

- Quick and Easy Maintenance: The extrusion line features a quickly replaceable embossing roller system. The specially designed calibration unit and accumulated production experience ensure long service life and easy operation.

- Online Punching Capability: The integrated punching machine realizes online punching of siding panels for economic efficiency. The system can also be equipped with rolling machines, ink jet printers, and other equipment based on your requirements.

- High Automation and Control: The entire extrusion line features high automation and can be equipped with a PLC automatic control system. This enables full-process automatic operation with real-time parameter monitoring and adjustment for improved efficiency.