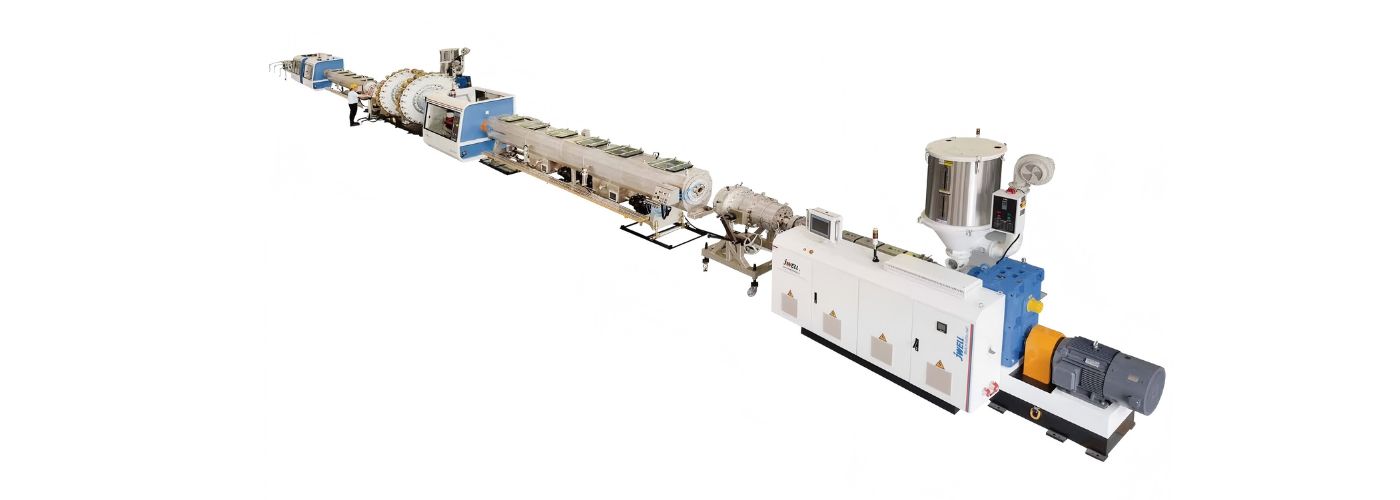

Steel Wire Reinforced Composite Pipe Production Line

Key Selling Points

- High-Speed Production: 30% faster than traditional lines

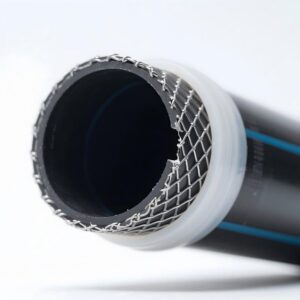

- Dual-Purpose Versatility: Produces both steel-reinforced and standard PE pipes

- High-Performance, Low Cost: 30-40% cheaper than pure PE pipes, high pressure rating (≥3.0MPa)

Main Technical Parameter

| Extruder Model | Output | Installed power | Pipe I.D. | Price |

| GS/PE-160G | 300-1200KG/H | 240 – 1100KW | 50 – 1600mm | USD 56K – 134K, FOB Shanghai |

| GS/PE-315G | 300-1200KG/H | 240 – 1100KW | 75 – 315mm | USD 56K – 134K, FOB Shanghai |

| GS/PE-630 | 300-1200KG/H | 240 – 1100KW | 315 – 630mm | USD 56K – 134K, FOB Shanghai |

| GS/PE-800 | 300-1200KG/H | 240 – 1100KW | 560 – 800mm | USD 56K – 134K, FOB Shanghai |

| GS/PE-1000 | 300-1200KG/H | 240 – 1100KW | 710 – 100mm | USD 56K – 134K, FOB Shanghai |

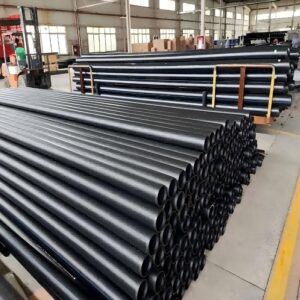

Application Scenarios

Product Description

The JWELL Steel Wire Reinforced Composite Pipe Production Line is an advanced high-speed manufacturing system engineered for efficient production of reinforced composite pipes with exceptional strength and cost efficiency.

- Next-Generation High-Speed Production: A newly developed, high-efficiency production line for steel wire reinforced composite pipes, with production speeds nearly 30% faster than traditional lines.

- Unmatched Production Versatility: This single line is capable of producing not only steel-reinforced composite pipes but also standard, national-grade pure polyethylene (PE) pipes for water and gas applications, significantly reducing project investment costs.

- Superior Cost-Performance Ratio: The resulting steel-reinforced pipes (50mm-1000mm) offer a 30-40% cost saving compared to pure PE pipes of the same specification and pressure grade, while delivering a superior working pressure rating of ≥3.0MPa.