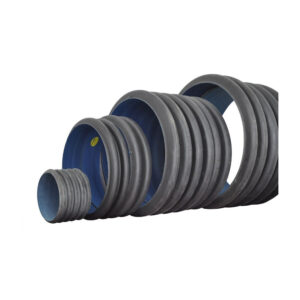

Vertical Type HDPE/PP/PVC Double Wall Corrugated Pipe Line

Key Selling Points

- Parallel Twin-Screw Extruders: Excellent mixing, direct powder/granule use, low material cost

- Integrated Side-Feeding System: On-the-fly filler ratio adjustment, easy formula changes

- Vacuum Degassing System: Dense, smooth, bubble-free inner & outer pipe walls

- Modular Screw & Barrel: Building-block design, easy formula optimization, low maintenance cost

Main Technical Parameter

| Raw Material | Extruder Model | Output | Type | Installed power | Dimensions (LxWxH) | Pipe I.D. | Price |

| HDPE | JWSBL-600 | 800KG/H | JWSBL-600 | 500KW – 800KW | 30mx5mx4m – 60mx8mx8m | 200 – 600mm | USD 14K – 1.39M, FOB Shanghai |

| PP | JWSBL-1000 | 1200KG/H | JWSBL-1000 | 500KW – 800KW | 30mx5mx4m – 60mx8mx8m | 200 – 1000mm | USD 14K – 1.39M, FOB Shanghai |

| PVC | JWSBL-1200 | 1400KG/H | JWSBL-1200 | 500KW – 800KW | 30mx5mx4m – 60mx8mx8m | 800 – 1200mm | USD 14K – 1.39M, FOB Shanghai |

Application Scenarios

Product Description

The JWELL Twin-Screw Large-Diameter Pipe Extrusion Line is a high-capacity manufacturing system engineered for efficient production of large-diameter HDPE, PP, and PVC pipes with exceptional mixing performance and material flexibility.

- Advanced Compounding & Extrusion: A state-of-the-art production line featuring two parallel twin-screw extruders for superior mixing performance, ideal for manufacturing large-diameter pipes (200-1200mm) with high filler content.

- Cost-Effective Direct Material Use: The system is engineered to directly process both powdered and granular raw materials, eliminating the need for a separate pelletizing stage and significantly reducing raw material costs.

- Flexible Formulation Control: Equipped with a dedicated side-feeding system that allows for the online adjustment of calcium powder or other filler ratios, making formula changes quick and convenient without interrupting production.

- Superior Pipe Quality & Finish: Each extruder incorporates vacuum vents to effectively remove volatiles, ensuring the final pipe has dense, smooth, and bubble-free inner and outer walls.