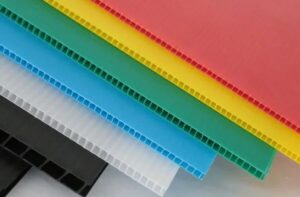

PVC Imitation Marble Board

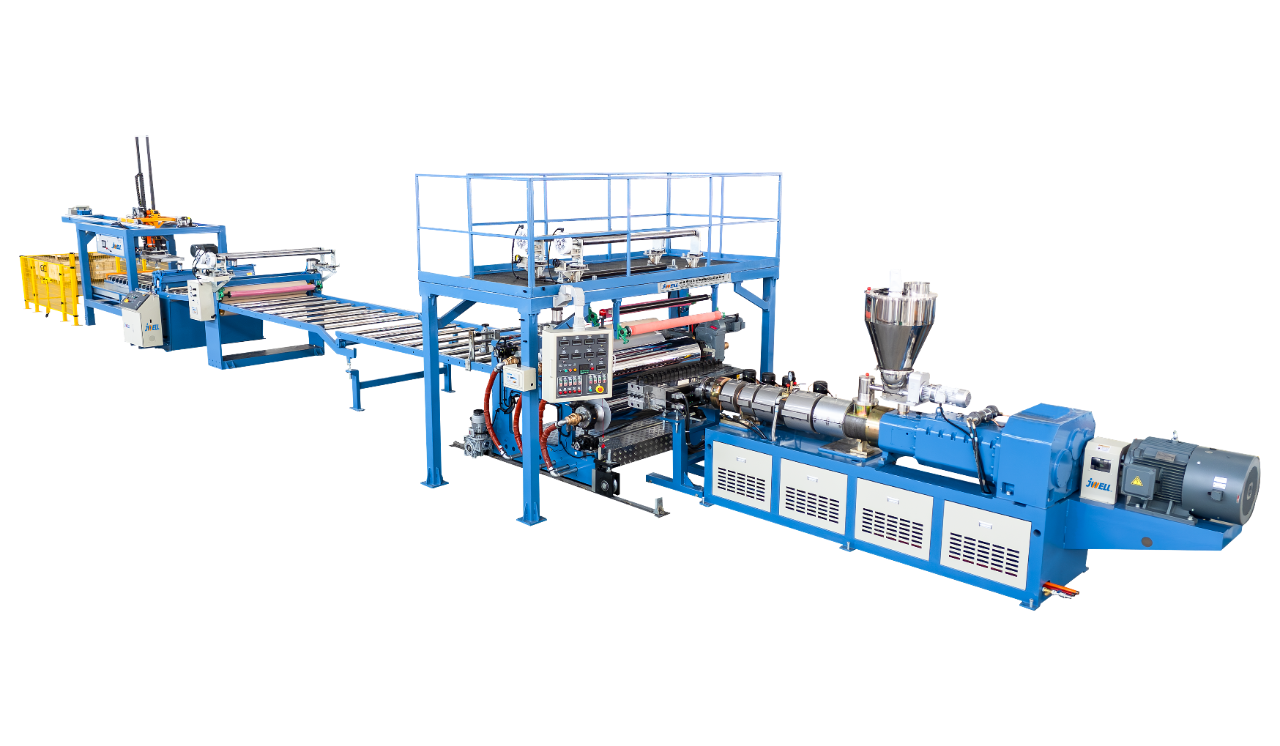

Against the backdrop of the global upgrade of architectural decoration materials, PVC imitation marble boards, due to their light weight, environmental friendliness, and high degree of realism, have become excellent alternatives to traditional stones. Through performance optimization, JWELL Company has perfectly integrated energy-saving extrusion and surface treatment technologies in its PVC imitation marble board extrusion line, enabling continuous production of high-quality boards. The online adjustment of the production process is more flexible, reducing the waste of time and material costs caused by adjustments to product specifications.

Main Features of the PVC Imitation Marble Board Extrusion Line

1.High Efficiency Extrusion System

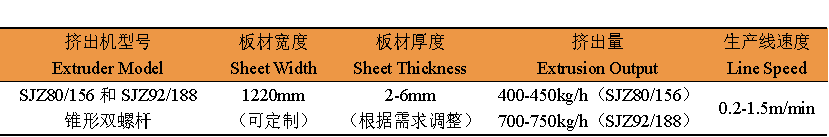

Adopt the SJZ80/156 and SJZ92/188 conical twin screw extruder, which is equipped with a special screw design to ensure that the PVC powder is fully plasticized and mixed, and the extrusion is stable and efficient.

The barrel adopts cast aluminum heating and air-cooling temperature control. The temperature control accuracy is ±1℃, ensuring the forming quality of the sheets.

Extrusion capacity: 400-450kg/h(SJZ80/156),700-750kg/h(SJZ92/188)

It can produce sheets with a width of 1220 mm and a thickness of 2-6mm.

2.Precision Calendering & Forming

An advanced four-roll calendering device with independent servo synchronous control ensures a smooth surface of the sheet.

A special roller temperature control system is designed to meet the cooling and shaping requirements of sheets with different thicknesses, reducing stress deformation.

3.UV Imitation Marble Board Surface Treatment

An optional lamination process (surface bonding of a marble-like film) or thermal transfer UV curing technology can be used to achieve realistic stone textures.

The treated sheets have the characteristics of scratch resistance, yellowing resistance, and ultraviolet resistance, and are suitable for indoor and outdoor decoration.

4.Automated Cutting & Stacking

The fixed-length cutting system features an accuracy error of ≤±0.5mm.

An automatic stacking manipulator can be optionally equipped, which reduces the need for manual labor and improves the packaging efficiency.

5.PLC Intelligent Control

An integrated Human – Machine Interface (HMI) is available to monitor key parameters in real – time, such as the load and pressure of the extruder, the temperature of the extruder and the die, and the speed of the rollers. It also supports data recording and process optimization.

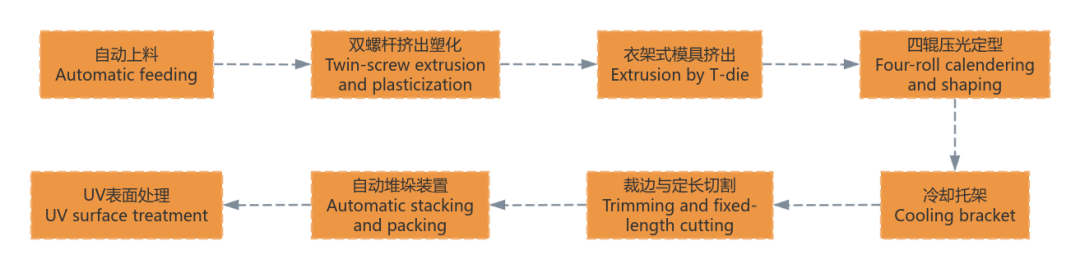

PVC Imitation Marble board Production Process

Main Technical Parameters

Product Advantages & Applications

Green and Environmentally Friendly: Formaldehyde-free, radiation-free, and compliant with EU RoHS standards.

Fireproof and Flame-retardant: Meets B1 fire protection standard, suitable for public places.

Easy to Install: Can be directly subjected to sawing, drilling, and nailing operations, with installation efficiency 50% higher than natural stone.

Architectural Decoration (hotels, shopping malls, office buildings) Home Decoration (wall surfaces, cabinets, ceilings)

Choose JWELL, Choose Excellence

- Chuzhou JWELL Intelligent Equipment Industrial Park

As a leading enterprise in China’s plastic extrusion industry, JWELL Machinery currently has eight production bases and more than thirty specialized companies, and its products are sold to over 120 countries and regions. Our PVC imitation marble board production line takes high stability, low energy consumption and intelligence as its core advantages, providing customers with one-stop services ranging from equipment delivery to process training.

Contact us to start a new chapter in the intelligent manufacturing of high-end decorative sheets!