PET sheet

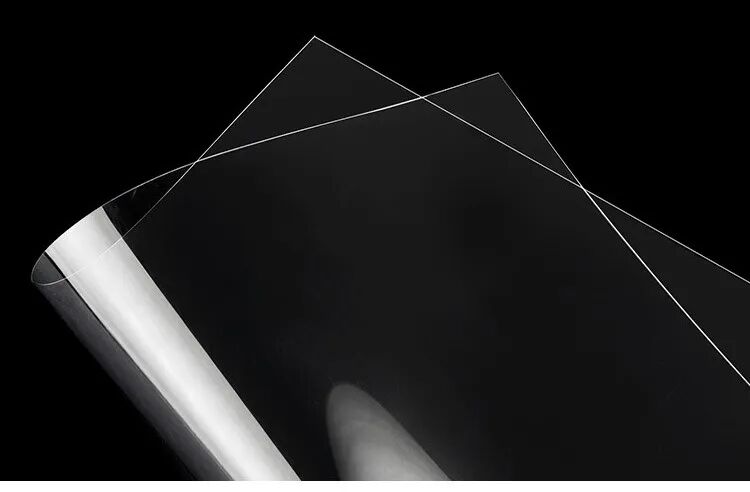

In the industrial wave of widespread plastic product applications, PET sheet materials have occupied a key position in packaging, electronics, medical and other fields with their core properties such as high transparency,excellent toughness, and chemica corrosion resistance. The high capacity PET sheet extrusion line created by JWELL Machinery through technological innovation has become a leading domestic sheetproduction solution by virtue of advanced processes, stable performance and high-efficiency production capacity.The production line not only improves the comprehensive eficiencyby about 30% compared with similar domestic equipment, but also is compatible with the production of multiple materials such as PLA, APET, PETG and CPET. Moreover, PET products can be recycled, which is deeply in line with the concept of circular economy and environmental protection.

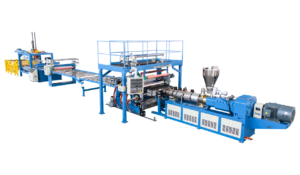

Main Features of the PET sheet extrusion line

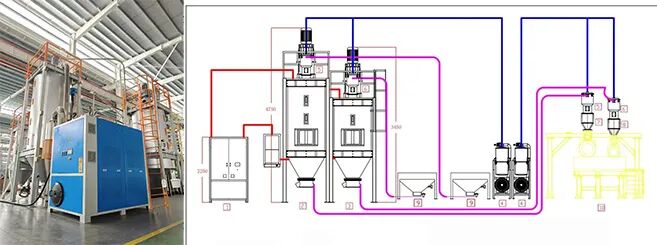

1.Crystallization, Dehumidification and Drying System

The three-stage treatment system, consisting of a crystallization barrel, dehumidifier and drying tower, prevents raw material agglomeration through crystallization pre-plasticization. Subsequently, through the dual effects of physical adsorption by the dehumidifer and heat conduction in the drying tower, the moisture content of the raw materials is controlled at an extremely low level. This process significantly enhances the melting uniformity of PET pellets, laying a solid foundation for subsequent plasticizing extrusion and ensuring the quality of the sheets.

2.PLC and HMI Intelligent Control System

Through the linkage between the industrial-grade PLC (Programmable Logic Controllerand HMI (Human-Machine Interface), dynamic collaborative control and real-time data feedback across the entire production process are achieved.

Intuitive and concise operation interface with high automation

Swift detection and response to production anomalies, ensuring stable and efficient operation throughout the process.

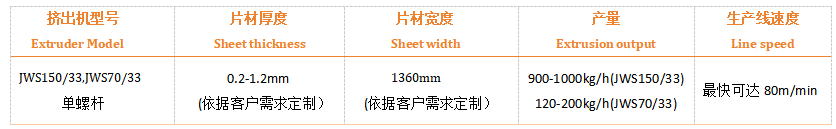

3.JWS150/33,JWS70/33 single screw extruder

As the core forming equipment, this extruder is specifically designed for high-quality PET sheets:Performance Advantages: When using virgin pellet raw materials, it produces sheets with high transparency,high viscosity, and excellent tensile properties, meeting the stringentrequirements of large-scale thermo formed products.Production Specifications: It can produce products with a thickness range of 0.08-2mm. The Maximum output of the entire production line can reach 1,200 kg/h and High-speed co-extrusion lines with 2-3 extruders: 1,000-3,000 kg/h, flexibly adapting to

diverse requirements.

4.Screw and Barrel Composite Process

Structural Innovation: The screw is manufactured using multi-material composite technology. After nitriding and quenching and tempering treatments, it features high surface hardness and excellent abrasion resistance. The special thread design optimizes material conveying efficiency,ensuring uniform plasticization and superior melt dispersibility.Energy-Saving Design: The barrel is equipped with far-infrared heaters, which are more energy-efficient than traditional resistance heating. They offer faster temperature rise and more uniform temperature field distribution.

5.T type mold

The T-type mold, featuring a hanger-type runner design and high-quality mold steel ensures a long service life and enables the production of high-precision, high-quality sheets.

6.J-type Three-roller Calender

Mechanical Structure: The J-type layout optimizes the force balance of the roller system. The working width ofthe rollers reaches 1,600 mm, and the mirror roller smoothness and cleanliness level is ≤0.016 um.

Drive Control: Equipped with a servo motor drive system, it features fast response speed and high roller speed control precision, enabling high-precision control of sheet thickness uniformity.

7.X-ray On-line Thickness Measurement System

The integrated high-precision X-ray thickness gauge conducts real-time scanning and monitoring of the sheet thickness. After the data is analyzed by the algorithm, it is synchronously fed back to the extruder and three-roll system to ensure that the thickness fluctuation of the sheet is controlled within a small range.

8.Multi-station Center Winding System

Adopting multi-station continuous winding, it supports continuous winding operations with large winding capacity and high effciency.

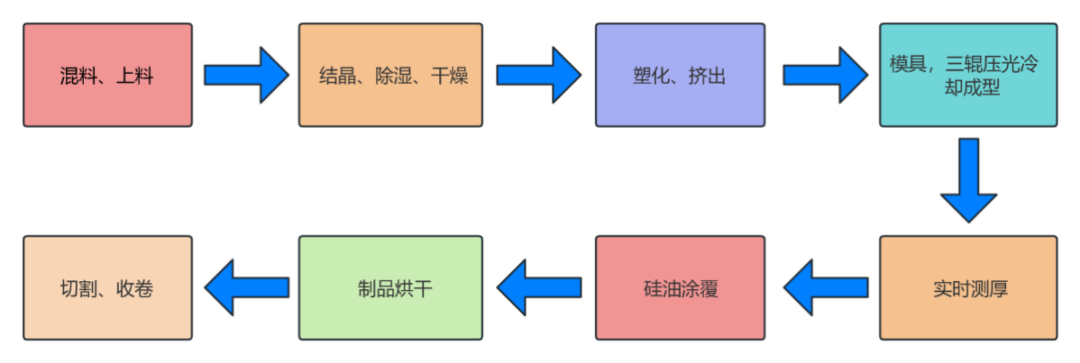

Production process

Main Technical Parameters

Product Advantages & Applications

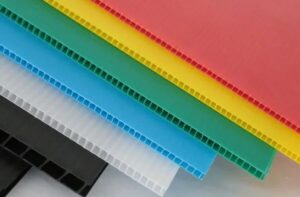

Low Mass: With a low density, it is over 50% lighter than glass in the same volume, significantly reducing transportation costs and energy consumption.

Safe and Non-toxic: Certified for food contact, it contains no harmfil substances and can directly contact food and pharaceuticals.

Recyclability:100% recyclable, enabling circular utilization through physical recycling (melting and pelletizing)or chemical recycling (depolymerization to monomers),aligning with sustainable development trends.

Application Areas:

Widely used in various industries such as food packaging, medical packaging, dailynecessities, cosmetic packaging, protective flm for electronic products, and etc.

Choose JWELL, Choose Excellence

As a leading enterprise in China’s plastic extrusion industry, JWELL Machinery drives industry development through global layout and technological innovation. At present, the company has built an industrial matrix of eight modern production bases and more than 30 professional companies, forming a full-chain system covering research and development, manufacturing, and services. With stable and reliable equipment performance, mature and superb process technology, and high-eficiency and low-consumption energy-saving advantages, our products are sold in more than 120 countries and regions, making us a trusted plastic extrusion solution provider for global customers.

JWELL Machinery always takes technological innovation as the engine and customer needs as the guide, deeply cultivating the plastic extrusion field. Whether in traditional plastic processing scenarios or emerging material application fields, we can provide you with adaptable intelligent and professional production lines.

Chuzhou JWELL welcomes all new and regular customers to inquire. We will customizethe exclusive plastic extrusion scheme for you with professional team and high-quality service.