Pipe Extrusion Line

Pipe extrusion lines operate with either cost-effective single-screw extruders for materials like PP and PE pellets, or more advanced twin-screw extruders. The twin-screw models provide superior mixing and are essential for directly processing PVC powder, which eliminates a separate granulation step and requires careful screw design due to PVC's heat-sensitive nature. Jwell Pipe Extrusion Lines are a trusted choice, known for their easy controls, stable performance, high-efficiency output, and long service life.

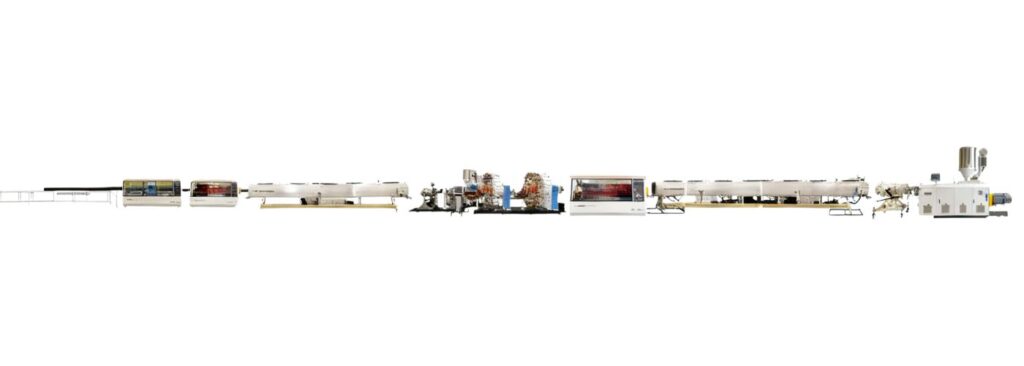

Small-diameter PE/PPR/PE-RT/PA Single-pipe, Dual-pipe High-speed Extrusion Production Line

Output: 160 - 420KG/H

Installed Power: 100KW - 3200KW

Dimensions(LxWxH): 20mx2mx3m - 40mx4mx7m

Price: USD 100K - 3M, FOB Shanghai

Small-diameter HDPE/PPR/PE-RT/PA Single-pipe, Dual-pipe High-speed Extrusion Production Line

Output: 160 - 420KG/H

Installed Power: 100KW - 3200KW

Dimensions(LxWxH): 20mx2mx3m - 40mx4mx7m

Price: USD 14K - 417K, FOB Shanghai

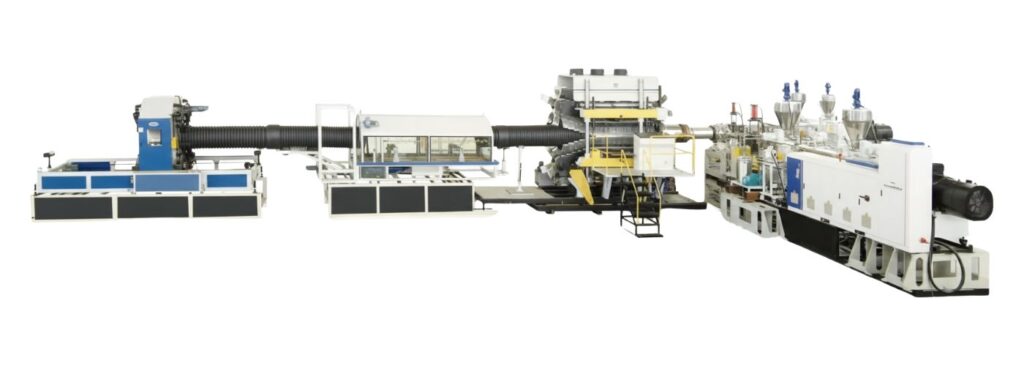

Horizontal Single/Double Wall Corrugated Pipe Production Line

Installed Power: 60KW - 100KW

Dimensions(LxWxH): 12mx3mx3m - 20mx5mx5m

Price: USD 30K - 600K, FOB Shanghai

Internal Embedded Cylindrical Drip Irrigation Pipe Production Line

Output: 500KG/H

Installed Power: 200KW

Dimensions(LxWxH): 30mx3mx5m

Price: USD 14K - 697K, FOB Shanghai

RTP Reinforced Pipe Extrusion Line

Output: 120 - 600KG/H

Installed Power: 230KW - 380KW

Dimensions(LxWxH): 40mx4mx4m - 60mx6mx6m

Price: USD 14K - 2.78M, FOB Shanghai

Vertical Type HDPE/PP/PVC Double Wall Corrugated Pipe Line

Output: 800 - 1400KG/H

Installed Power: 500KW - 800KW

Dimensions(LxWxH): 25mx2mx5m - 50mx2mx8m

Price: USD 14K - 1.39M, FOB Shanghai

β-PPH/PVDF High-Efficiency Pipe Extrusion Production Line

Output: 280 - 850KG/H

Installed Power: 283KW - 696KW

Dimensions(LxWxH): 25mx2mx5m - 50mx2mx8m

Price: USD 14K - 696K, FOB Shanghai

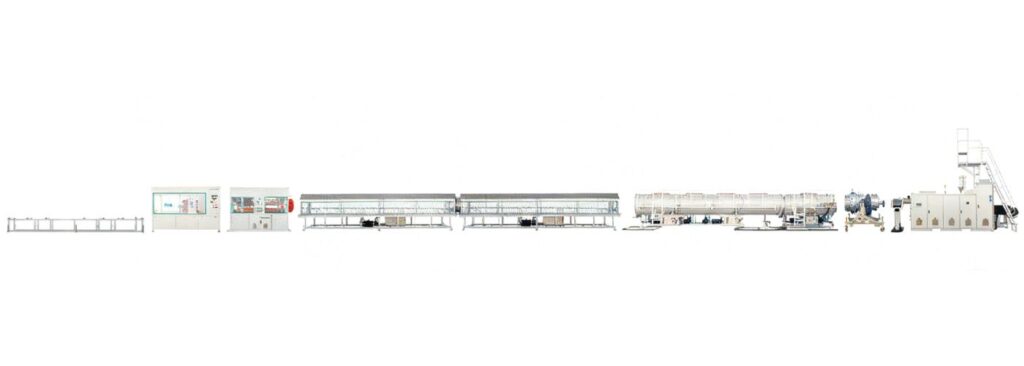

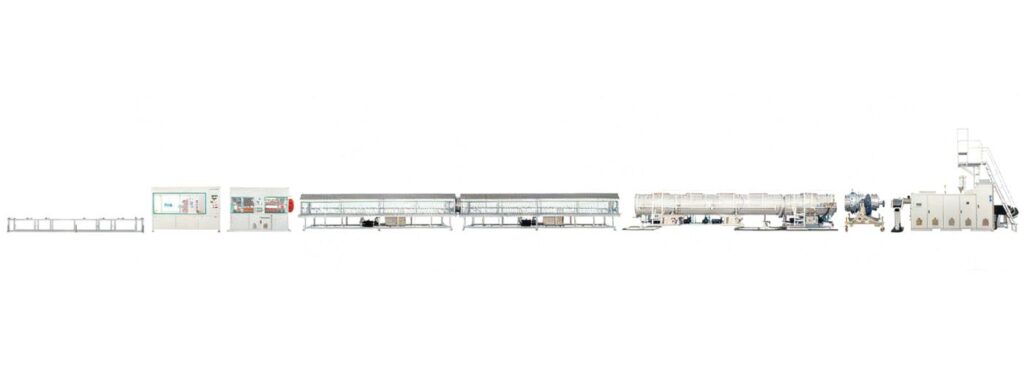

High-speed Energy-saving HDPE Solid Wall Pipe Extrusion Line

Output: 350 -1050KG/H

Installed Power: 200KW - 700KW

Dimensions(LxWxH): 30mx3mx3m - 70mx5mx10m

Price: USD 14K - 697K, FOB Shanghai

Steel Wire Reinforced Composite Pipe Production Line

Output: 300-1200KG/H

Installed Power: 240KW - 1100KW

Dimensions(LxWxH): 50mx6mx5m - 100mx10mx10m

Price: USD 56K - 134K, FOB Shanghai

MPP Polypropylene Power Cable Conduit Extrusion Production Line

Output: 380 - 730KG/H

Installed Power: 205KW - 580KW

Dimensions(LxWxH): 45mx3mx4m - 60mx5mx5m

Price: USD 55K - 208K, FOB Shanghai

Horizontal Double Wall Corrugated Pipe Production Line

Output: 400 - 1300KG/H

Installed Power: 400KW - 600KW

Dimensions(LxWxH): 12mx3mx3m - 20mx5mx5m

Price: USD 14K - 2.78M, FOB Shanghai

High Speed Surface Mounted Drip Irrigation Tape Production Line

Output: 5000KG/H

Installed Power: 210KW

Dimensions(LxWxH): 30mx10mx3m

Price: USD 10K - 3M, FOB Shanghai

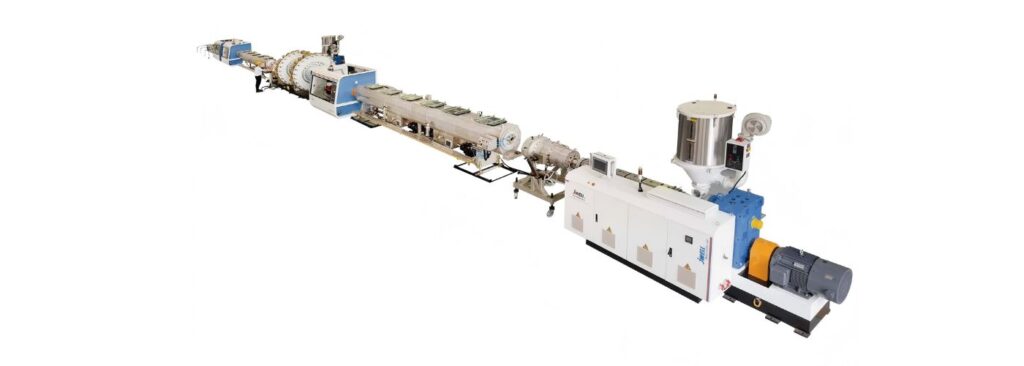

UPVC Pipe Extrusion Line

Output: 250 - 1400 KG/H

Installed Power: 106KW - 322KW

Dimensions(LxWxH): 25mx3mx2.8m - 44mx5mx3m

Price: USD 27K - 974K, FOB Shanghai

PE Insulation Pipe Extrusion Line

Output: 500 - 1300

Installed Power: 260KW - 632KW

Dimensions(LxWxH): 35m*3m*3m - 60m*5.5m*6m

Price: 2.7W - 111W

PVC Conical Twin Screw Extruder Hot-Cut Granulation Extrusion Line

Output: 800-900 KG/H

Installed Power: 180KW / 220KW

Dimensions(LxWxH): 10mx2mx4m

Price: USD 56K - 134K, FOB Shanghai