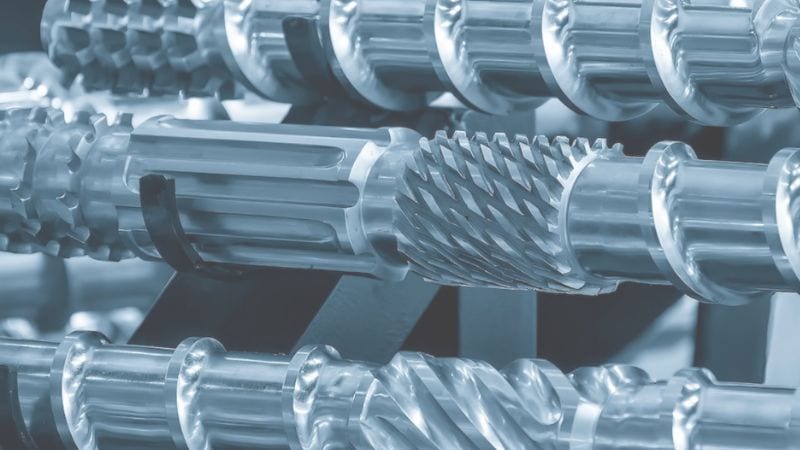

A well-chosen screw can boost throughput, improve melt quality, and reduce scrap, giving you faster, more reliable production.

In this guide, we’ll break down the most common extruder screw types, explore their types, best uses, and how geometry changes impact performance, so you can choose the right screw for your process.

Types Of Extrusion Screws

Every extruder screw is engineered to solve specific processing challenges, whether it’s basic conveyance, efficient melting, intensive mixing, or volatile removal. Selecting the right type is the first step toward optimizing your extrusion line.

Single-Flighted (Standard) Screws

As the most common and economical design, the single-flighted screw uses one continuous helical flight. Material is conveyed, compressed, and melted as the channel depth gradually decreases from the feed zone to the metering zone. This design offers predictable output and is easy to maintain and refurbish.

- Ideal For: Steady throughput of standard homopolymers and general-purpose compounds with good flow and low filler content.

- Common Uses: Found in many film, sheet, and pipe applications.

- Limitations: Less effective for high-filler materials or polymers requiring aggressive melt homogenization. Performance can often be upgraded by adding a downstream mixing section.

The Barrier Screw

This design incorporates a secondary flight that separates the main channel into two parallel paths: a shallow channel for the melt and a deeper channel for solid pellets. This “barrier” forces more efficient solids conveyance and melting, leading to reduced unmelted material, improved temperature stability, and often higher output with better energy efficiency.

- Ideal For: Semi-crystalline polymers (like HDPE and PP) and high-throughput applications where achieving a complete, uniform melt is critical.

- Common Uses: Precision film and sheet extrusion, and processing resins prone to unmelted particles.

- Limitations: Higher initial cost and more complex manufacturing. Performance is highly sensitive to the clearance and length of the barrier flight, requiring precise design and tuning.

The Mixing Screw

Mixing screws integrate specialized elements—such as Maddock, pin, or kneading sections—into their design to enhance the dispersion and distribution of additives, fillers, or colorants. These elements introduce controlled shear to homogenize the melt.

- Ideal For: Filled compounds, masterbatches, and any application where achieving uniform color, additive dispersion, or particle deagglomeration is a priority.

- Common Uses: Compounding, production of color concentrates, and engineering resins with high filler loads.

- Limitations: Generates higher shear and melt temperature, requiring careful thermal management. Increased torque and wear necessitate the use of hardened materials or coatings when processing abrasive additives.

The Vented (Two-Stage) Screw

Vented or two-stage screws have a pressure-controlled melt stage followed by a low-pressure, vacuum-capable zone to remove volatiles and moisture. This gives you controlled degassing for hygroscopic polymers, solvent-bearing blends, and food ingredients sensitive to trapped gases. The design often combines a deep feed section, compression section, and a downstream venting/second-stage channel with a relieved flight or port.

Select vented screws when moisture or gases cause porosity, bubbles, or poor surface finish. Proper vacuum port placement and downstream pumping are essential to avoid re-entrainment of gases. Vented designs can reduce downstream drying steps but require more complex barrel hardware and careful process tuning.

Applications: Matching the Screw to the Product

The ultimate driver for screw selection is your end product. Different applications impose unique demands on melt quality, mixing, and stability. Here’s how major application areas dictate screw choice.

Pipes and profiles (construction, irrigation)

Extrusion screws in plastics and rubber help convert raw pellets or powders into continuous shapes like pipes, sheets, and profiles. You control product dimensions and surface quality by selecting the right screw geometry and length-to-diameter ratio.

Films and sheets (packaging, liners)

Film, fiber, and sheet production require smooth melt flow and tight pressure control. Matching screw channel depth and compression to your polymer and line speed reduces melt temperature variations and defects.

Compounds and masterbatches (colorants, additives)

For highly filled or reinforced materials, twin-screw or specially profiled single screws provide the necessary shear and conveying capacity. These configurations prevent clogging and improve throughput with glass-filled, mineral-loaded, or recycled resins.

Food/feed products (extruded snacks, kibble)

Food and feed industries use extrusion screws to cook, texturize, and form products such as snacks, cereals, and pet food. Twin-screw designs give better mixing, heat transfer, and precise control for ingredient-sensitive recipes.

Technical compounds (filled, reinforced polymers)

For highly filled or reinforced materials, twin-screw or specially profiled single screws provide the necessary shear and conveying capacity. These configurations prevent clogging and improve throughput with glass-filled, mineral-loaded, or recycled resins.

How Screw Design Affects Plastic Extrusion

Screw geometry controls how material moves, melts, and mixes, which determines output rate, energy use, melt quality, and how the line operates. Your choice of compression ratio, flight depth, and mixing elements directly changes throughput, product uniformity, and ease of running the line.

Mastering Throughput and Energy Efficiency

- Channel Design & Pitch: The volumetric capacity of the feed zone and the flight pitch primarily set your maximum possible throughput. Deeper channels and aggressive pitches move more material but demand more torque.

- Compression Ratio (CR): This ratio (feed depth/metering depth) controls the melting aggression. A higher CR speeds melting, potentially increasing output, but at the risk of higher shear heat and motor load.

- L/D Ratio & Efficiency: A longer screw (higher L/D) provides a gentler, more gradual melting profile, which can lower peak torque and reduce specific energy consumption. Features like barrier flights also promote efficient melting with less wasted energy.

- Material Matters: Beyond geometry, sustained efficiency requires wear resistance. Hardened alloys or coatings maintain the precise channel geometry, preventing throughput drops and energy waste caused by increased clearance from wear.

Ensuring Product Quality and Consistency

- Melt Homogeneity: The screw’s melting profile—dictated by transition zone design—determines the completeness of melt and temperature uniformity. A poor design leads to unmelted solids or temperature spikes, causing defects like gels or weak spots.

- Mixing & Dispersion: As discussed, the type and placement of mixing elements directly control the distribution of additives, directly impacting mechanical properties, color, and surface appearance.

- Pressure Stability: A consistent, stable head pressure is vital for dimensional control. The length and tolerance of the metering zone are key to damping out pressure fluctuations that cause thickness variations in sheet or pipe.

- Residence Time Control: The screw’s flow path must minimize “dead spots” where material can stagnate and degrade. This is especially critical for heat-sensitive polymers (like PVC) to prevent burning and maintain consistent viscosity.

Achieving Operational Stability and Ease of Use

- Start-up & Purging: A well-designed screw with a logical compression profile will start up predictably and purge cleanly during material or color changes, reducing downtime.

- Surge Prevention: Screws that promote stable melting (e.g., barrier designs) are less prone to output surging, which disrupts gauge control and increases scrap.

- Maintenance & Longevity: The choice between tight clearances (for better pumping) and looser clearances (for contaminant tolerance) is a key maintenance trade-off. Designs that operate smoothly at lower RPMs reduce stress on the drive train.

- Self-Cleaning: Features like steep flight angles in the feed zone can help sweep the barrel clean, facilitating faster changeovers.

Conclusion

The extruder screw is the central architect of your process, dictating material movement, melting efficiency, and final mix quality. Its geometry doesn’t just affect performance—it defines it.

Choosing the optimal screw requires a clear analysis of your polymer, desired output rates, and quality targets. Always consider the trifecta of geometry, metallurgy, and special features.

Use this checklist to guide decisions:

- Match screw profile to material (e.g., barrier for difficult melts).

- Verify metallurgy for abrasion and corrosion resistance.

- Plan maintenance intervals based on operating hours and wear.

- Test scale-up before full production changes.

If you adjust screw geometry, run controlled trials to measure melt temperature, pressure, and product quality. Document results to repeat successes and avoid surprises.

Find Your Complete Plastic Extrusion Line?

JWELL manufactures comprehensive lines for pipes, profiles, sheets, and pelletizing. Our twin-screw extruders are renowned for PVC processing, while each line is tailored, integrating your required output, material, and product specifications.

You’ll find detailed specifications, solutions tailored to your specific needs, and more information on how our advanced equipment can elevate your production capabilities. Explore range of our products and contact us for more information.