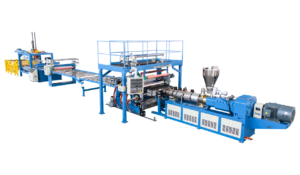

From the pipes that carry our water to the packaging that keeps our food fresh, extruded plastics are an invisible part. This guide will walk you through the various types of extruders to help you understand which machine is the perfect fit for your manufacturing needs.

Single-Screw Extruder vs. Twin-Screw Extruder

A. Single Screw Extruders

The single-screw extruder is the most fundamental and widely used design in the industry.

- How They Work: It’s a beautifully simple concept. A single, long screw rotates inside a heated barrel. Raw material (usually in pellet form) is fed in at one end. As the screw turns, it moves the material through three distinct zones:

- Feed Zone: The material is picked up and conveyed forward.

- Compression (or Melting) Zone: The screw’s channel depth decreases, compressing the material against the barrel wall. This, combined with external heat, melts the plastic.

- Metering Zone: The molten plastic is homogenized and pushed out through the die at a consistent rate.

- Advantages: Their simple design makes them cost-effective to purchase and maintain. They are reliable and straightforward to operate, especially for processing simple, pelletized plastics.

- Disadvantages: They offer limited mixing capability, making them unsuitable for materials requiring high-intensity blending or the addition of fillers. Their output can also be slower compared to more advanced models.

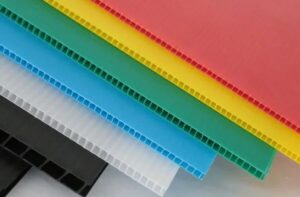

- Best For: Creating uniform products like pipes, plastic sheets, and simple profiles.

B. Twin Screw Extruders

When your process demands superior mixing, compounding, or higher output, the twin-screw extruder is the answer.

- How They Work: As the name suggests, these machines feature two intermeshing screws rotating within the barrel. This design drastically improves conveying and mixing efficiency.

- Key Variations:

- Co-rotating vs. Counter-rotating: In co-rotating extruders, both screws spin in the same direction, creating intense shear and exceptional mixing—perfect for compounding. Counter-rotating screws spin in opposite directions, making them ideal for processing heat-sensitive materials like PVC.

- Conical vs. Parallel: These terms refer to the screw shape. Conical twin-screw extruders are particularly effective for PVC processing due to the high pressure they generate.

- Advantages: They deliver incredibly high output and fast speeds. Their superb mixing ability makes them the go-to choice for creating custom plastic compounds (compounding) or colored plastics (masterbatch). Many are also self-cleaning, which significantly reduces downtime between material changes.

- Best For: Compounding, masterbatch production, and processing materials that require significant mixing or gentle heating.

|

Feature

|

Single-Screw Extruder

|

Twin-Screw Extruder

|

|

Mixing Capability

|

Low to moderate

|

High to very high

|

|

Cost

|

Generally lower

|

Generally higher

|

|

Material Handling

|

Good for many standard polymers

|

Excellent for a wide range of materials, including heat‑sensitive or challenging ones

|

|

Applications

|

Commonly used for simple profiles (pipes, sheets) with many standard materials, though some materials (e.g. PVC) are often processed on twin‑screw extruders

|

Widely used for compounding, masterbatch, reactive extrusion, and for materials such as PVC profiles and pipes

|

|

Output Rate

|

Generally lower for the same size and conditions

|

Generally higher for the same size and conditions

|

|

Maintenance

|

Simpler mechanical structure and maintenance

|

More complex structure and maintenance

|

In-Depth Analysis of Twin-Screw Extrusion Machine

Twin-screw extruders can be further classified based on their rotation, design, and geometry.

Based on Screw Rotation

- Co-rotating Twin-Screw Extruders: Both screws rotate in the same direction. This is the most common type, offering excellent mixing and high throughput. The material is conveyed from one screw to the other, creating a figure-eight pattern that enhances distributive and dispersive mixing.

- Counter-rotating Twin-Screw Extruders: The screws rotate in opposite directions. This design creates a calendering effect, making it suitable for processing shear-sensitive materials like PVC. The material is conveyed in a C-shaped channel.

Based on Screw Design

- Intermeshing Twin-Screw Extruders: The flights of one screw engage with the channels of the other. This is the most common design and provides a self-wiping action, which prevents material from stagnating and overheating.

- Non-intermeshing Twin-Screw Extruders: The screws are separated and do not intermesh. This design behaves more like two single-screw extruders working in parallel and is less common.

Based on Screw Geometry

- Parallel Twin-Screw Extruders: The screws have a constant diameter along their entire length. They are versatile and used for a wide variety of compounding applications.

- Conical Twin-Screw Extruders: The screw diameter decreases from the feed zone to the metering zone. This design allows for higher pressure buildup, making them particularly effective for extruding rigid PVC profiles and pipes.

Specialized and Emerging Extruder Machines

Ram Extruders: For High-Viscosity Materials

Ram extruders, also known as plunger extruders, use a hydraulic ram to push material through the barrel and die. They are used for materials with extremely high viscosity that cannot be processed with a rotating screw, such as PTFE (Teflon). The process is typically performed in batches.

3D Printer Extruders: Direct Drive vs. Bowden

While on a much smaller scale, the extruders found on 3D printers share the same basic principles and are worth knowing.

- Direct Extruders: The motor that pushes the filament is mounted directly on the print head. This gives it precise control, making it great for printing with soft, flexible filaments. The downside is that the extra weight can limit print speed.

- Bowden Extruders: The motor is mounted on the printer’s frame, pushing the filament through a long tube to the hotend. This makes the print head much lighter, allowing for faster and smoother movements. However, it can be less reliable with flexible filaments.

Multi-Screw Extruders and Other Innovations

Research and development continue to push the boundaries of extrusion technology. Multi-screw extruders with three or more screws are being explored for highly specialized mixing applications. Other innovations include integrated process control with AI and machine learning to optimize output and quality in real-time.

Applications of Extruders Across Industries

- Plastics and Polymers: This is the largest field of application, including the production of pipes, siding, window frames, decking, fencing, plastic films for packaging, and much more.

- Food and Feed Processing: Extruders are used to cook and shape a wide variety of products, including breakfast cereals, pasta, snack foods, and pet food. The process can create specific textures and shapes that are difficult to achieve otherwise.

- Pharmaceuticals and Medical Devices: Hot-melt extrusion is used to create drug-eluting devices and controlled-release dosage forms. Extruders are also used to manufacture medical tubing and catheters.

How to Choose the Right Extruder for Your Business

Selecting the ideal extruder comes down to four key questions:

- What material are you processing? (e.g., PVC powder, PC pellets, a custom compound?)

- What is your final application? (e.g., large-diameter pipe, thin film, small-profile trim?)

- What is your required production rate? (e.g., kilograms per hour?)

- Do you need to mix in additives? (e.g., colorants, fillers, UV stabilizers?)

Here’s a quick-reference table to help guide your decision:

|

Extruder Type

|

Advantages

|

Disadvantages

|

Common Applications

|

|

Single-Screw

|

Cost-effective, simple design

|

Slower, poor mixing

|

Pipes, sheets, profiles

|

|

Twin-Screw

|

High output, excellent mixing

|

More complex, expensive

|

Compounding, masterbatch, PVC

|

|

Ram

|

Uniform heating, minimal waste

|

Slower, often intermittent

|

UHMWPE, medical implants

|

Conclusion: Your Partner in Extrusion

The choice between a single-screw, twin-screw, or a more specialized machine depends entirely on your material, your product, and your production goals. As technology advances, we’re seeing more automated, energy-efficient, and versatile extruders capable of handling a new generation of sustainable and bioplastic materials.

For expert guidance on your specific needs, contact us today. Our team of experienced professionals is ready to help you find the ideal solution to elevate your production process and achieve your manufacturing goals.

Frequently Asked Questions (FAQs)

1. What is the difference between molded and extruded plastics?

Molded plastics are created by injecting molten plastic into a three-dimensional mold to create a specific shape. In contrast, extruded plastics are made by forcing molten plastic through a die to form a continuous two-dimensional profile, like a pipe or a window frame.

2. What are the size limitations for extruded profiles?

The size of an extruded profile can vary significantly depending on the manufacturer’s equipment. Some companies can produce extrusions up to 18 inches wide or even wider in some cases . The length of extrusions can also be quite long, with some manufacturers capable of producing profiles over 24 feet in length. Flexible profiles can be coiled or spooled to the desired length .

3. What is co-extrusion or dual durometer?

Co-extrusion, also known as dual durometer, is a process where two or more materials with different physical properties are fused together into a single extruded piece. A common example is a rigid part with flexible “fingers” that act as a gasket. Typically, materials from the same polymer family are used to ensure proper adhesion.

4. Is it possible to create extrusions with multiple colors?

Yes, it is possible to create extrusions with two or more colors. This process is called co-extrusion, where multiple extruders feed different colored materials into a single die .

5. Why is PVC a popular choice for extrusion?

PVC is a popular material for custom extrusions because its compounds range from very soft to very rigid, making it suitable for a wide range of requirements. It can be easily colored and is inherently flame resistant with good chemical resistance. Additives can also be included to improve its weatherability.

6. Are there environmentally friendly options in plastic extrusion?

Yes, some manufacturers are exploring more environmentally friendly options in plastic extrusion. This includes working with “green initiative materials,” wood-filled plastic compounds, and non-PVC materials . Additionally, some companies focus on recycling plastic waste to use in their extruders .