Extrusion and injection molding are two fundamentally different manufacturing processes. Extrusion molding pushes material through a die to create continuous shapes with the same cross-section, while injection molding forces molten plastic into a mold cavity to produce individual parts with complex designs. Understanding which process suits your needs can significantly impact your production efficiency, costs, and final product quality.

What is Extrusion Molding?

Extrusion molding is a manufacturing process that creates long, continuous parts with a consistent cross-section. Plastic pellets are fed into a hopper, where a screw mechanism moves the material forward while heating it.

The extrusion process can use hot extrusion—where material is heated above its melting point—or cold extrusion at room temperature. As the screw pushes the molten plastic forward, it builds pressure and forces the material through a specially shaped die that determines the final shape.

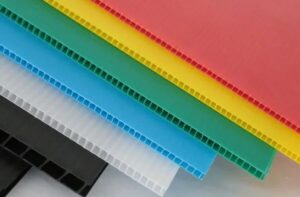

Once the material exits the die, you get continuous profiles that can be cut to any length. Common plastic extrusion applications include pipes, tubing, window frames, weatherstripping, and cable insulation. This approach is ideal for high-volume production of uniform shapes because the manufacturing process runs continuously without stopping. This continuous extrusion method is especially efficient when you need long, consistent profiles rather than individual molded parts.

What is Injection Molding?

Injection molding creates individual three-dimensional parts with precision and detail. Plastic pellets are loaded into a hopper, and a screw mechanism heats and melts them as they move through a heated barrel inside the injection molding machine. Here, the pellets are melted into a homogeneous plastic resin before being forced into the mold under high pressure.

The molten plastic is injected under high pressure into an injection mold, where the mold cavity shapes your part. Sprues and runners guide the material to all areas of the mold, ensuring complete filling.

After the mold fills completely, the material cools and solidifies. The mold then opens, and the finished part is ejected. Mold design is critical for success—it requires proper cooling channels, venting, and ejection systems.

This process excels for complex parts that need tight tolerances or detailed features. You can create parts with logos, textures, threads, and snap-fit features in a single molding cycle.

Core Differences Between Extrusion and Injection Molding

Injection molding and extrusion differ fundamentally in production method, design capabilities, cost structure, and material efficiency.

Production Method & Output

The injection molding process creates discrete parts, typically 30 seconds to a few minutes per cycle. In contrast, extrusion molding produces continuous lengths of 100 to 1,000+ feet that you cut to size later. This fundamental difference makes each process suited to different manufacturing goals.

Design Complexity & Precision

Injection molding handles complex three-dimensional geometries with intricate details, undercuts, threads, and varying wall thicknesses. The injection mold tool delivers tight tolerances and smooth surface finishes on all sides.

Extrusion is limited to two-dimensional profiles with consistent cross-sections along their entire length. While the extrusion process can create complex profiles with internal voids, the cross-sectional profile remains uniform from end to end.

Comparison

- Injection mold capabilities: Full 3D shapes, enclosed cavities, variable geometry

- Extrusion capabilities: 2D profiles, consistent cross-sections, linear shapes

Cost Structure

Injection mold creation requires significant upfront investment—thousands to tens of thousands of dollars. However, the cost per plastic part drops dramatically at higher volumes, making injection molding cost-effective for large production runs of 5,000+ units.

Extrusion tooling costs approximately 80% to 90% less than injection mold tools. The cost per foot of extruded product remains relatively consistent regardless of volume, making extrusion molding ideal for smaller production runs or cost-sensitive projects.

Material Efficiency & Waste

Both processes generate waste, but in different ways. Injection molding creates waste from runners, sprues, and gates; most manufacturers recycle this material back into production. Extrusion molding produces less waste during continuous production, though trimming and startup material still require recycling.

Generally, extrusion uses material more efficiently for simple shapes, while injection molding offers better overall efficiency for complex geometries because less material is wasted per finished part.

Advantages & Disadvantages

Extrusion Molding: Pros and Cons

Advantages

- Lower upfront costs make plastic extrusion more affordable to start

- Continuous production creates long pieces without stops

- Works with multiple materials (plastic and metal, especially aluminum)

- Simple cross-sections produce in large quantities cost-effectively

Disadvantages

- Limited complexity—cannot create intricate three-dimensional shapes

- Fewer material options compared to injection molding

- Higher per-unit costs for small, complex parts

- Size restrictions—parts must have uniform cross-sections along their length

Injection Molding: Pros and Cons

Advantages

- Complex shapes with fine details for medical devices, toys, and electronics

- High precision creates identical parts with tight tolerances

- Fast production cycles of 30 seconds or less once your mold is ready

- Many material choices for automotive and packaging industries

Disadvantages

- High initial costs for mold tools

- Longer lead times before first parts arrive due to mold creation

- Limited to plastic in most cases

- Design changes are expensive once the mold tool is created

How to Choose: Injection Molding vs. Extrusion Molding

The right choice depends on three key factors: your plastic part requirements, production volume, and budget.

Choose plastic injection molding if you need:

- Complex 3D shapes with detailed features

- Medical devices or high-precision consumer goods

- Products with tight curves, threads, or intricate designs

- Tight dimensional tolerances (±0.005 inches or better)

- High volumes (5,000+ units) to justify tooling cost

Choose plastic extrusion if you need:

- Long, continuous shapes with consistent cross-sections

- Pipes, tubes, rails, or weatherstripping

- Cost-effective production at lower volumes

- Uniform profiles that can be cut to various lengths

- Quick tooling and faster time-to-production

Consider these three factors

Budget: Injection molding demands more upfront investment but becomes economical at scale. Plastic extrusion has lower setup costs, making it ideal for budget-conscious projects.

Production volume: For 10,000+ identical complex parts, injection molding delivers better per-unit costs. For long runs of simple profiles (under 5,000 units), extrusion molding makes economic sense.

Timeline & flexibility: Injection molding requires weeks for mold creation. Extrusion starts faster because tooling is quicker, and design modifications are simpler and less costly.

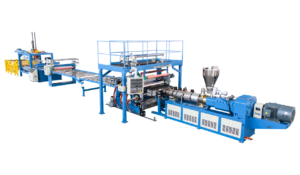

Jwell – Your Partner in High-Performance Extrusion

At Jwell, we specialize in the R&D and manufacturing of high-tech plastic extrusion molding equipment. Our team of expert mechanical and electrical engineers is dedicated to delivering precision-engineered production lines that maximize efficiency and product quality. Whether you are scaling up or starting a new project, we provide the innovative machinery and technical support you need to succeed in the global market.

Ready to optimize your production? Contact us for more information.

Frequently Asked Questions

Which process is faster, extrusion or injection molding?

Plastic extrusion is generally faster for continuous production runs. Plastic injection molding works in cycles—each cycle includes filling the mold, cooling, and ejecting. For producing individual complex parts quickly, injection molding offers faster cycle times (30 seconds to a few minutes). For high-volume continuous simple profiles, extrusion molding wins on overall speed and throughput.

Which process produces better quality parts, extrusion or injection molding?

Plastic injection molding produces parts with tighter tolerances (as tight as ±0.005 inches). Extrusion molding creates parts with commercial tolerances. Choose based on whether you need precision-grade accuracy or commercial-grade accuracy for your application.

What’s the minimum order quantity for extrusion vs. injection molding?

Plastic extrusion has lower minimums because tooling costs significantly less. Plastic injection molding typically requires higher minimums (500–1,000+ units) to justify mold costs, though prototype molds using soft steel or aluminum cost considerably less than production-grade hardened steel molds.

Can the extrusion molding process produce hollow profiles?

Yes, plastic extrusion commonly makes pipes and tubes using a mandrel in the die center. Plastic injection molding cannot create hollow parts; you must design two separate pieces that snap together, adding assembly steps and costs.

Can parts be modified after the injection molding or extrusion molding process?

Extruded products support secondary operations like cutting, drilling, and stamping. Injection-molded parts come nearly complete from the mold but can also undergo finishing. Both processes support painting, printing, and assembly, though extrusion allows more post-production flexibility.