Hot extrusion handles tough alloys and complex shapes. Cold extrusion delivers tighter tolerances, better surface finish, and often lower energy use. Choose hot extrusion for large, hard-to-form metals and complex geometries; choose cold extrusion when precision, surface quality, and strength from strain hardening matter.

This post gives you clear definitions of both processes, compares their mechanics and trade-offs, and guides your decision based on material, shape, cost, and production scale.

Definitions: What Is Hot Extrusion and Cold Extrusion?

The two processes differ by temperature, material behavior, tooling needs, and typical applications. You will see differences in mechanical properties, surface finish, and production scale.

Hot Extrusion

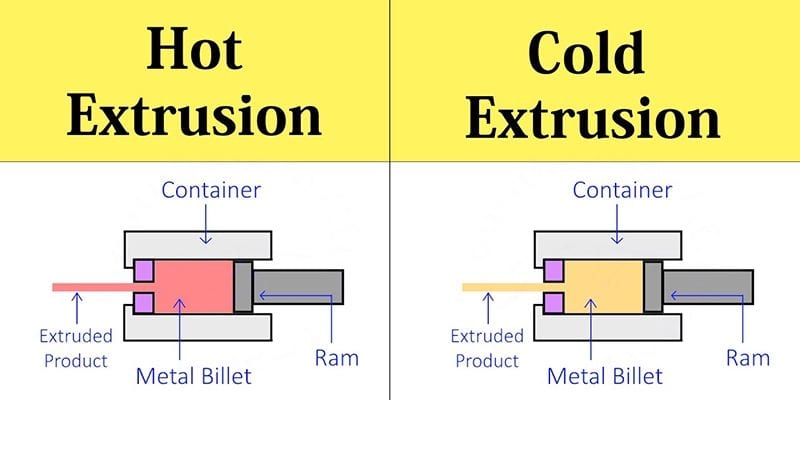

- Process Principle: Metal is forced through a die while heated above its recrystallization temperature.

- Key Effect of Heat: Reduces the metal’s flow stress, allowing the shaping of tough alloys (e.g., steel, titanium) with lower forces.

- Material Structure: Results in a coarser grain structure, which improves ductility but may reduce strength compared to cold-worked parts.

- Tooling Impact: Elevated temperatures can shorten tool life due to increased wear and oxidation.

Cold Extrusion:

- Process Principle: Metal is forced through a die at or near room temperature using significantly higher pressures. A dedicated lubrication process (e.g., phosphate coating combined with lubricating oil) is essential to prevent seizing and ensure superior surface quality.

- Material Property: The process cold-work hardens the material, increasing its yield strength and fatigue resistance. This makes it highly beneficial for components like fasteners and gears.

- Tooling & Lubrication Demands: Tooling must withstand extremely high stresses. While it benefits from greater dimensional stability due to the absence of heat cycling, effective lubrication (phosphate coating + oil system) is critical to manage friction, reduce wear, and guarantee both part finish and tooling longevity.

Hot vs. Cold Extrusion: What’s the Difference

Hot extrusion uses elevated temperatures to soften metals and reduce forming forces; cold extrusion keeps temperatures near room level to preserve strength and surface finish. Each method changes material flow, tool stress, tolerances, and post-processing needs in distinct ways.

Input Differences: Billet state, energy type (thermal vs. mechanical)

For hot extrusion, the input billet is heated, requiring significant thermal energy. This preheating makes the material softer and easier to deform. Cold extrusion, on the other hand, starts with a room-temperature billet, relying solely on intense mechanical force (pressure) to achieve deformation. This means the material must be carefully selected for its cold-working properties.

Output Differences: Part properties straight off the press

Hot extruded parts often require subsequent heat treatment to achieve desired mechanical properties, and their surface finish can be rougher, requiring secondary machining. Cold extruded parts emerge with improved surface finish, enhanced mechanical properties due to work hardening (like increased tensile strength and hardness), and often closer dimensional tolerances, frequently reducing or eliminating the need for further finishing.

Speed & Scale: Production rate and typical part size comparisons

Hot extrusion, especially for large profiles, can be a faster continuous process, ideal for long runs and large structural components. Cold extrusion, while sometimes slower per operation due to the higher forces involved, excels in high-volume production of smaller, intricate parts where precision and consistency are paramount.

Process Workflow Comparison

Hot extrusion heats the billet—often to 300–600°C for aluminum or higher for steel—before forcing it through a die. Heating lowers yield strength and increases ductility, so you use higher ram speeds and lower press tonnage relative to material strength. You must control temperature uniformity and billet oxidation.

Cold extrusion begins with a room-temperature or slightly warm billet and relies on higher forming pressures. You often use multiple stages (forward, backward, combined) with lubrication and close die tolerances to limit surface damage.

You typically need annealing, pickling, or machining after hot extrusion to correct grain growth or surface scale. Cold-extruded parts usually require less machining but need robust tooling and presses to handle the increased forces.

Advantages & Limitations: A Balanced View

Hot extrusion makes forming tough alloys easier because high temperatures lower flow stress. This reduces press tonnage and tooling wear, letting you make complex profiles, thin walls, and multi-void hollows more reliably.

However, surface finish and dimensional precision are lower. Hot-extruded parts often need secondary machining or heat treatment to meet tight tolerances and surface requirements.

Cold extrusion achieves tighter tolerances and a smoother surface right out of the die. Strength is improved through strain hardening, which is useful for high-strength small parts and fast production of consistent components.

Cold processing needs higher forming loads and stronger tooling. It limits the range of alloys that can be formed at room temperature and requires lubrication and careful handling to avoid cracks.

Use this quick comparison table to pick the right process for your needs:

| Factor | Hot Extrusion | Cold Extrusion |

| Formability of difficult alloys | Excellent | Limited |

| Tooling stress / press tonnage | Lower | Higher |

| Surface finish & tolerances | Poorer; often needs finish | Better; tighter tolerances |

| Strength effects | May require heat treatment | Work hardening increases strength |

| Typical applications | Large, complex profiles | Small precision parts |

Take the Next Step with JWELL

Hot extrusion is ideal for forming robust alloys into complex profiles, while cold extrusion excels in producing high-precision, work-hardened parts at scale. JWELL is a trusted partner in translating these manufacturing requirements into dependable, high-quality extrusion solutions.

Don’t miss the chance to explore full range of tailored extrusion solutions—visit our product page now to browse detailed product specifications, application cases, and contact us for more information.