A pulp molding machine is industrial equipment that converts waste paper or plant fibers into three-dimensional molded pulp products. Through pulping, forming, pressing, and drying, it transforms a fiber slurry into strong, lightweight items such as egg trays, fruit trays, cup carriers, industrial inserts, and eco-friendly tableware.

In other words, a pulp molding machine is the core technology behind many biodegradable, fiber-based packaging products now replacing foam and plastic packaging.

Why Pulp Molding Equipment Matter for Packaging Industry

Tightening environmental regulations and growing consumer awareness are driving a rapid shift away from single-use plastics and non-recyclable packaging. Pulp molding machines offer a practical solution by turning low-cost, recycled paper and agricultural fibers into high-value, sustainable packaging.

They support a circular economy: using waste as a resource, reducing landfill volumes, and lowering overall carbon footprint. For producers in food, agriculture, electronics, and logistics, this technology has become a strategic investment.

Paper Pulp Molding Applications at a Glance

| Common Uses | Industry Applications |

| Food and Fragile Product Packaging |

|

| Eco-Friendly Disposable Tableware |

|

| Electronics and Premium Packaging |

|

| Other Sectors |

|

How a Pulp Molding Machine Works

A pulp molding machine starts with a slurry of fibers made from waste paper, cardboard, or plant residues. This slurry is pumped into a forming tank. A metal mesh mold is partially submerged in the pulp, and a vacuum is applied from inside the mold. The vacuum draws fibers to the mold surface, building up a wet layer that matches the mold shape.

The wet product is then transferred, dewatered further, dried, and, if necessary, hot-pressed and trimmed. Key parameters such as pulp concentration, vacuum pressure, forming time, and drying temperature are carefully controlled for consistent quality.

Types of Pulp Molding Machines

By Technology

Rotary pulp molding machines

- Use a rotating drum or carousel equipped with multiple molds.

- Designed for continuous, high-volume production, especially for egg trays and similar standard items.

Reciprocating pulp molding machines

- Use mold plates that move back and forth between the pulp tank and transfer section.

- Suitable for small to medium output and for factories that need flexibility and frequent mold changes.

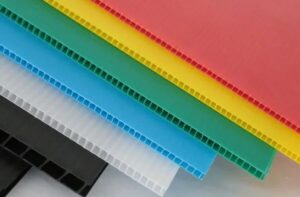

Thermoformed (hot-press) pulp molding machines

- Combine forming and hot pressing to produce high-precision, smooth-surface products.

- Commonly used for premium packaging for electronics, cosmetics, and high-grade disposable tableware.

By Automation Level and Capacity

Manual pulp molding machines

- Low investment and simple to operate.

- Depend more on manual handling and often use basic drying methods.

- Best for small workshops, pilot projects, and very low production volumes.

Semi-automatic pulp molding machines

- Automate forming and some transfer steps, with partial manual work in drying or stacking.

- A good fit for small to mid-sized manufacturers looking to grow.

Fully automatic pulp molding machines

- Integrate pulping, forming, drying, counting, and stacking in a continuous line.

- Deliver high output with minimal labor and are ideal for large-scale production.

Machines are also categorized by capacity, usually measured in pieces per hour. The right size depends on your product mix, sales targets, and available factory space.

Main Components of Pulp Molding Machines

A complete pulp molding production line typically includes:

| Pulping system |

|

| Forming system |

|

| Drying system |

|

| Hot-pressing and trimming (for higher-value products) |

|

| Auxiliary systems |

|

Pulp Molding Machines Working Process: Step-by-Step

1. Raw material preparation

Waste paper, cardboard, or plant fibers are collected, sorted, and sometimes pre-cut to improve pulping efficiency.

2. Pulping

Raw materials are mixed with water in a hydrapulper to form a uniform slurry. Operators adjust fiber mix and consistency to match product requirements.

3. Screening and refining

The pulp passes through screens and cleaners to remove contaminants such as plastic and metal. Refiners may be used to optimize fiber length and bonding.

4. Pulp supply to forming tank

The cleaned pulp is pumped into the forming tank. Automatic controls maintain stable pulp concentration, essential for uniform product thickness.

5. Forming (vacuum molding)

The forming mold is immersed in the pulp. Vacuum draws fibers toward the mold mesh, building a wet layer. After the target thickness is reached, the mold leaves the tank.

6. Transfer and dewatering

A transfer mold or plate picks up the wet product. Further vacuum or compressed air helps remove more water and release the product cleanly from the mold.

7. Drying

Products enter the drying line, where controlled temperature and airflow remove remaining moisture until the items are fully dry and rigid.

8. Hot pressing and finishing (optional)

For high-end packaging and tableware, dried items are hot-pressed to improve density, smoothness, and dimensional accuracy, then trimmed or printed as required.

9. Stacking and packaging

Finished products are counted, stacked, and packed for storage or shipment, often using automated stacking equipment.

Benefits of Using a Pulp Molding Machine

Environmentally Friendly

A pulp molding machine offers strong environmental advantages:

- Uses recycled materials, such as waste paper and agricultural residues, reducing landfill waste.

- Produces biodegradable and often compostable packaging that breaks down naturally.

- Replaces EPS foam and many plastic trays, helping companies comply with plastic reduction policies.

- Modern lines often feature water recycling and efficient heat use, reducing overall resource consumption.

Cost-Effectiveness

From a cost perspective:

- Raw materials are low-cost and widely available.

- When molds and process parameters are optimized, product yield is high and scrap rates are low.

- Lightweight molded pulp packaging can lower shipping costs compared to heavier or bulkier alternatives.

Although initial investment for a fully automatic line can be significant, ongoing savings in material, labor, and logistics—combined with growing market demand—often generate attractive returns.

Productivity and Efficiency

Modern pulp molding machines are designed for reliable, efficient operation:

- Fully automatic lines can produce thousands of trays or packages per hour.

- PLC control and standardized forming conditions help maintain consistent quality.

- Quick mold-change systems allow manufacturers to switch between products with minimal downtime.

This combination of output, quality, and flexibility makes pulp molding equipment suitable for both standard mass products and customized packaging.

Market and Brand Benefits

Using molded pulp packaging supports a clear sustainability message. Consumers increasingly favor brands using recyclable and fiber-based packaging, and retailers appreciate easy-to-recycle materials.

By investing in a pulp molding machine, businesses not only improve their environmental performance but also differentiate their products in the marketplace.

How to Choose the Right Pulp Molding Machine

Define Product and Capacity Requirements

Start by clarifying:

- Product types (egg cartons, tableware, industrial packaging, etc.)

- Dimensions, thickness, and surface quality needed

- Daily and annual production targets

Consider Size, Capacity, and Layout

- Match the machine’s output (pieces per hour) to your projected demand, allowing some margin for growth.

- Check the floor space required for pulping, forming, drying, and packing sections.

- Review available power and heat sources (electricity, gas, steam, biomass) and their local operating costs.

Select the Right Automation Level

- Manual machines: for very small operations with low budgets and abundant labor.

- Semi-automatic machines: for growing factories that need better efficiency without the cost of a full automatic line.

- Fully automatic machines: for large producers or those planning high-volume, long-term production.

Evaluate Mold Design and Flexibility

Molds largely determine product quality and versatility:

- Ask about mold material, precision, and expected service life.

- Confirm whether the supplier offers custom mold design and sample testing.

- Check typical mold change-over times if you plan to run multiple product types.

Assess Energy and Environmental Performance

Operating costs are heavily affected by energy and water use. Look for:

- Efficient, well-insulated dryers and possible heat recovery systems.

- Water recycling and filtration solutions.

- Options to utilize economical local fuels or heat sources.

Choosing a Reliable Supplier

When selecting a pulp molding machine supplier, consider:

- Experience and number of successful installations

- Reference projects similar to your planned application

- Availability of installation, commissioning, and operator training

- After-sales support and spare parts supply

- Compliance with local safety and quality standards

A reliable supplier will help design the right configuration and support you throughout the machine’s service life.

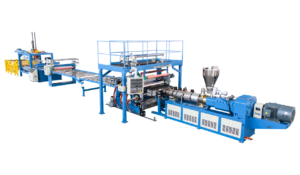

Take Your Next Step with Jwell – Pulp Molding Machine Manufacturer

For your eco-friendly packaging needs, consider Jwell. Backed by the extensive R&D and engineering expertise of its strategic manufacturing center, we deliver high-performance, reliable pulp molding solutions.

Jwell provides a complete range of equipment, from fully automatic production lines for premium meal kits to flexible semi-automatic systems for industrial packaging. They also offer essential finishing equipment like hot presses and trimming machines to ensure a high-quality final product. Partner with Jwell to build an efficient and sustainable packaging operation.